Aluminium Washers

Aluminium Washers

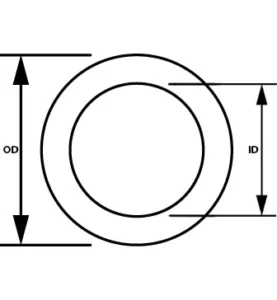

| Aluminium Washers Datasheet | ||||

|---|---|---|---|---|

| For Screw Size | OD | ID | Thickness Range | Specs. Met |

| M1 | 3.2 mm | 1.1 mm | 0.2 mm to 0.4 mm | DIN 125 |

| M1.2 | 3.8 mm | 1.3 mm | 0.2 mm to 0.4 mm | DIN 125 |

| M1.4 | 3.8 mm | 1.5 mm | 0.2 mm to 0.4 mm | DIN 125 |

| M1.6 | 4.0 mm | 1.7 mm | 0.2 mm to 0.4 mm | DIN 125, ISO 7089 |

| M2 | 5.0 mm | 2.2 mm | 0.2 mm to 0.4 mm | DIN 125, ISO 7089 |

| M2.5 | 6.0 mm | 2.7 mm | 0.4 mm to 0.6 mm | DIN 125, ISO 7089 |

| M3 | 7.0 mm | 3.2 mm | 0.4 mm to 0.6 mm | DIN 125, ISO 7089 |

| M3.5 | 8.0 mm | 3.7 mm | 0.4 mm to 0.6 mm | DIN 125, ISO 7089 |

| M4 | 9.0 mm | 4.3 mm | 0.7 mm to 0.9 mm | DIN 125, ISO 7089 |

| M5 | 10.0 mm | 5.3 mm | 0.9 mm to 1.1 mm | DIN 125, ISO 7089 |

| M6 | 12.0 mm | 6.4 mm | 1.4 mm to 1.8 mm | DIN 125, ISO 7089 |

| M7 | 14.0 mm | 7.4 mm | 1.4 mm to 1.8 mm | DIN 125, ISO 7089 |

| M8 | 16.0 mm | 8.4 mm | 1.4 mm to 1.8 mm | DIN 125, ISO 7089 |

| M10 | 20.0 mm | 10.5 mm | 1.8 mm to 2.2 mm | DIN 125, ISO 7089 |

| M12 | 24.0 mm | 13.0 mm | 2.3 mm to 2.7 mm | DIN 125, ISO 7089 |

| M14 | 28.0 mm | 15.0 mm | 2.3 mm to 2.7 mm | DIN 125, ISO 7089 |

| M16 | 30.0 mm | 17.0 mm | 2.7 mm to 3.3 mm | DIN 125, ISO 7089 |

| M18 | 34.0 mm | 19.0 mm | 2.7 mm to 3.3 mm | DIN 125, ISO 7089 |

| M20 | 37.0 mm | 21.0 mm | 2.7 mm to 3.3 mm | DIN 125, ISO 7089 |

Aluminium Washers – Pressed Parts are precision‐fabricated components produced by pressing aluminium sheet metal into washers designed to distribute load and provide an effective sealing surface in fastener assemblies. Manufactured by Conex Metals using advanced pressing techniques, these washers offer a cost‐effective and reliable solution in applications where lightweight, corrosion‐resistant components are required. We are one of the largest manufacturers and suppliers of Aluminium Washers from India. Our manufacturing plant in Jamnagar, India, offers a wide range of Aluminium Washers, and we export our products worldwide to some of the most quality-conscious markets in the world.

Key Features of Aluminium Washers

High-Quality Material:

Made from premium aluminium alloys (such as 6061 or equivalent), these pressed washers combine excellent corrosion resistance with lightweight strength, making them ideal for various industrial and consumer applications.Precision Pressing Process:

Using high-precision power presses and compound dies, the washers are cold-formed with tight tolerances, ensuring consistent dimensions and a smooth, uniform surface finish.Variety of Standards:

Typically produced to comply with international standards (for example, DIN 125 for flat washers or BS 4320 for plain washers), they are available in a wide range of sizes and thicknesses—from thin shims to thicker, load-distributing washers.Cost-Effective Production:

The pressing process allows for high-volume production with minimal waste, offering a competitive price per kilogram (e.g., around $11 per kilogram) without compromising on quality.

Technical Specifications (Example Values)

| Parameter | Specification (Typical) |

|---|---|

| Material Grade | Aluminium 6061 or similar alloy |

| Standard Compliance | DIN 125 / BS 4320 |

| Thickness Range | 0.1 mm to 3 mm (customizable) |

| Diameter Range | Commonly available from 4 mm up to 50+ mm (various standard sizes) |

| Tolerance | ±0.005 mm to ±0.02 mm, depending on size and application |

| Finish | Polished or anodized for enhanced corrosion resistance and aesthetic appeal |

*Note: Specific dimensions and tolerances may be tailored to meet customer requirements.

Applications of Aluminium Washers

Fastener Assemblies:

Used under bolts and screws to distribute load evenly and reduce surface damage on mating parts.Sealing and Insulation:

Provide a reliable sealing surface in applications where vibration damping or insulation from metal-to-metal contact is required.Electro-Mechanical Systems:

Ideal for electrical enclosures, automotive assemblies, and industrial machinery where lightweight, high-strength components are critical.Decorative and Structural Uses:

Their clean, uniform appearance makes them suitable for both functional and decorative applications in consumer products and architectural elements.

Advantages of Aluminium Washers

Lightweight & Strong:

Aluminium’s high strength-to-weight ratio reduces overall system weight without sacrificing performance.Corrosion Resistance:

Naturally resistant to rust and oxidation, these washers are ideal for use in outdoor or harsh environments.Precision Engineering:

High-quality pressing techniques ensure consistent, reliable performance with tight dimensional tolerances.Cost Efficiency:

High-volume production using advanced pressing methods results in competitive pricing and low material waste.

By choosing Conex Metals’ Aluminium Pressed Washers, you secure a precision-engineered, cost-effective component that enhances the performance and longevity of your assembly. These washers are designed to meet stringent quality standards and provide reliable, repeatable results in a wide range of industrial and consumer applications.