Brass Roto Moulding Inserts

Brass Roto Moulding Inserts

BSP (G) Roto Molding Inserts Standard Range

Brass Roto Moulding Inserts AKA ‘Rotational Moulding inserts’ are specialized metal inserts designed for use in rotational (roto) molding applications. Engineered to be integrated directly into a molded thermoplastic part during the rotational molding cycle, they provide a permanent, high-strength threaded connection that overcomes the inherent limitations of softer plastic threads. Manufactured from high-quality Brass at our advanced facility in Jamnagar, India, our Roto Moulding Brass Inserts are recognized for their precision, durability, and superior craftsmanship.

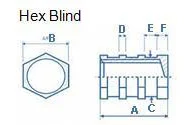

| THREAD | A | B | C | D | E | F | GROOVES |

|---|---|---|---|---|---|---|---|

| M4 | 8.5 | 8 | 6.1 | 1.5 | 2 | 1.5 | 2 |

| M5 | 10 | 8 | 6.1 | 1.7 | 2.5 | 1.6 | 2 |

| M6 | 10 | 10 | 7.7 | 1.7 | 2.5 | 1.6 | 2 |

| M6 | 15 | 10 | 7.7 | 1.7 | 2.5 | 2.4 | 3 |

| M8 | 16 | 12 | 9.8 | 1.7 | 2.5 | 3.4 | 3 |

| M8 | 19 | 12 | 9.4 | 9.8 | 2.5 | 2.2 | 4 |

| M10 | 16 | 14 | 11.8 | 1.7 | 2.5 | 3.4 | 3 |

| M10 | 19 | 14 | 11.8 | 1.7 | 2.5 | 2.2 | 4 |

| M12 | 19 | 16 | 13.5 | 1.7 | 2.5 | 2.2 | 4 |

| M14 | 19 | 18 | 15.8 | 1.7 | 2.5 | 2.2 | 4 |

Key Features of Brass Roto Moulding Inserts

Integrated Design:

Roto Moulding Inserts are embedded into the plastic during the molding process, ensuring precise alignment and a strong mechanical bond with the host material.Material Quality:

Typically manufactured from high-quality brass (with options available in stainless steel), these inserts offer excellent corrosion resistance and durability, which is critical for applications exposed to moisture or varying temperatures.Consistent Thread Formation:

The inserts are engineered to form reliable internal threads that can accommodate standard screws or bolts, providing a robust fastening solution without the need for secondary machining or repair operations.Optimized for Roto Molding:

Their design is specifically tailored to the unique conditions of rotational molding, where the material flow and cooling rates require an insert that can maintain thread integrity over large production volumes.

Technical Specifications (Example Values)

| Parameter | Specification (Typical) |

|---|---|

| Material | Brass (options in stainless steel available) |

| Thread Sizes | Available in a range (e.g., M3 to M12) |

| Insert Length | Approximately 1.25–1.5× the nominal thread diameter |

| Integration Method | Embedded during the roto molding process |

| Finish | Polished brass for enhanced corrosion resistance |

Note: Exact dimensions and thread pitches can be customized to meet specific application requirements.

Applications of Roto Moulding Inserts

Rotationally Molded Components:

Ideal for creating permanent, metal-threaded interfaces in plastic parts produced via roto molding.Consumer Products:

Used in items such as storage tanks, automotive components, and outdoor furniture where a robust and reliable threaded connection is needed.Industrial & Commercial Systems:

Employed in systems where repeated assembly/disassembly is impractical, ensuring long-term structural integrity.

Advantages of Roto Moulding Inserts

Enhanced Durability:

By providing a metal thread within a molded part, these inserts significantly improve the load-bearing capacity and longevity of the assembly compared to directly molded plastic threads.Cost Efficiency:

Integrated during the molding process, they eliminate the need for additional secondary operations, reducing production time and costs.Improved Consistency:

The in-mold integration ensures that every insert meets tight dimensional tolerances, resulting in uniform, high-quality threaded connections across large production runs.Versatile Use:

Suitable for various roto molding applications, they can be tailored to the specific mechanical and environmental demands of your product.

By choosing Conex Metals’ Brass Roto Moulding Inserts, you secure a high-performance, cost-effective solution for producing robust, permanent threaded connections in roto molded plastic parts.