Stainless Steel Washers – Pressed Parts

Stainless Steel Washers – Pressed Parts

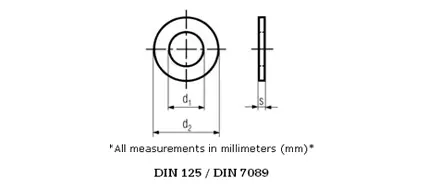

| Stainless Steel Washers Datasheet | |||

|---|---|---|---|

| d1 | for thread size | d2 | s |

| 1.7 | M1.6 | 4 | 0.3 |

| 2.2 | M2 | 5 | 0.3 |

| 2.7 | M2.5 | 6 | 0.5 |

| 3.2 | M3 | 7 | 0.5 |

| 3.7 | M3.5 | 8 | 0.5 |

| 4.3 | M4 | 9 | 0.8 |

| 5.3 | M5 | 10 | 1 |

| 6.4 | M6 | 12 | 1.6 |

| 7.4 | M7 | 14 | 1.6 |

| 8.4 | M8 | 16 | 1.6 |

| 10.5 | M10 | 20 | 2 |

| 13 | M12 | 24 | 2.5 |

| 15 | M14 | 28 | 2.5 |

| 17 | M16 | 30 | 3 |

| 19 | M18 | 34 | 3 |

| 21 | M20 | 37 | 3 |

| 23 | M22 | 39 | 3 |

| 25 | M24 | 44 | 4 |

| 28 | M27 | 50 | 4 |

| 31 | M30 | 56 | 4 |

| 34 | M33 | 60 | 5 |

| 37 | M36 | 66 | 5 |

| 40 | M39 | 72 | 6 |

| 43 | M42 | 78 | 7 |

| 50 | M48 | 92 | 8 |

| 54 | M52 | 98 | 8 |

Stainless Steel Washers – Pressed Parts are precision‐fabricated components engineered from high-quality stainless steel using advanced pressing techniques. Manufactured by Conex Metals, these washers deliver excellent dimensional accuracy, uniform surface finish, and robust performance, making them ideal for a wide range of industrial, automotive, plumbing, and architectural applications. As a trusted manufacturer and global supplier, we produce Stainless Steel Washers at our state-of-the-art facility in Jamnagar, India, meeting the stringent quality standards demanded by industries worldwide.

Key Features of Stainless Steel Washers

Premium Material:

Constructed from high-grade stainless steel (such as grades 304 or 316), these washers offer outstanding corrosion resistance, durability, and strength in harsh environments.Precision Pressing Process:

Produced via advanced power presses and compound dies, the washers are cold-formed to tight tolerances. This process ensures consistent thickness, smooth edges, and uniform dimensions, meeting strict international standards.Versatile Design:

Available in various inner and outer diameters and thicknesses, they can be tailored to specific fastener sizes and application requirements. They are designed to distribute load evenly and reduce localized stress.Aesthetic and Functional Appeal:

With a clean, polished finish, these pressed washers not only perform reliably but also enhance the overall appearance of assemblies.

Technical Specifications (Example Values)

| Parameter | Specification (Typical) |

|---|---|

| Material Grade | Stainless Steel (e.g., 304, 316) |

| Thickness Range | 0.2 mm to 3.0 mm (customizable) |

| Outer Diameter Range | Available in standard sizes (e.g., 10 mm to 100+ mm) |

| Inner Diameter | Designed to match standard fastener shank sizes (e.g., for M4 to M12 bolts) |

| Tolerance | Generally within ±0.005 mm to ±0.02 mm |

| Surface Finish | Polished or optionally treated for enhanced corrosion resistance |

*Note: Actual dimensions and tolerances can be customized based on specific customer requirements.

Applications of Stainless Steel Washers

- Fastener Assemblies:

Used beneath bolts and screws to distribute load and protect mating surfaces from damage. - Plumbing and Structural Installations:

Provide a reliable sealing and load distribution solution in plumbing, automotive, and industrial assemblies. - Architectural and Decorative Uses:

Their polished finish makes them suitable for visible applications where both functionality and aesthetics are important. - Industrial Machinery:

Employed in equipment where durability and precision are critical for long-term performance.

Advantages of Stainless Steel Washers

- Enhanced Corrosion Resistance:

Stainless steel’s inherent properties ensure longevity even in corrosive or outdoor environments. - Consistent Quality and Precision:

Advanced pressing technology results in uniform parts with tight tolerances, ensuring repeatable performance in high-volume production. - Load Distribution:

The washer’s design effectively spreads the fastener’s load, reducing the risk of surface deformation or damage. - Customization and Flexibility:

Available in a wide range of sizes and finishes, they can be tailored to meet diverse application needs without compromising on quality.

By choosing Conex Metals’ Stainless Steel Washers – Pressed Parts, you ensure a high-performance, reliable, and aesthetically pleasing component that enhances both the structural integrity and overall appearance of your assemblies.