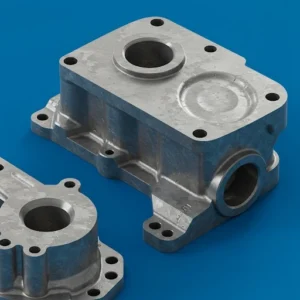

Aluminum Gravity Die Casting Parts

Aluminum Gravity Die Casting Parts

Aluminum Die Casting components and Die cast Aluminum Parts- Precision Engineered Components

Aluminum Die Casting components and Die cast Aluminum Parts- Precision Engineered Components

We are one of the leading manufacturers and exporters of Aluminum Gravity Die Casting Parts from India. We have been supplying these precision-engineered components to the world market for many decades. Our state-of-the-art manufacturing facility in Gujarat, India, is equipped with advanced tilting-type gravity casting machines operated by skilled technicians with extensive experience in metallurgy and casting technologies. Our commitment to quality, precision engineering, and adherence to international standards has established us as a trusted partner for industries requiring high-performance Aluminum Parts and Aluminum components. With a focus on continuous improvement and technological innovation, we’ve expanded our capabilities to serve diverse sectors including electrical, power transmission, plumbing, HVAC, fluid control systems, and industrial machinery across global markets. Our dedication to consistent quality, customization capabilities, and on-time delivery has earned us long-standing relationships with clients worldwide.

Product Overview

Product Overview

Aluminum Gravity Die Casting (also known as permanent mold casting) is a sophisticated metal forming process where molten Aluminum is poured into reusable metal molds under the force of gravity rather than under high pressure as in traditional die casting. This process yields components with exceptional dimensional accuracy, superior surface finish, and excellent mechanical properties. Our tilting-type gravity casting machines allow for controlled metal flow, resulting in castings with minimal porosity and superior structural integrity.

Our Aluminum gravity die cast parts are engineered to meet the exacting standards of various industrial applications. With wall thicknesses ranging from 3mm to 25mm and weights from 50g to 20kg, our capabilities encompass a wide spectrum of component sizes and complexities. The permanent mold casting process enables the production of complex geometries with internal passages, precise threading, and integrated mounting features that would be challenging or impossible to achieve with other manufacturing methods. Each component undergoes rigorous inspection and testing to ensure consistent quality and performance across production batches.

Material Specifications

Material Specifications

We work with a comprehensive range of Aluminum alloys, each selected for specific application requirements:

Commonly Used Alloys in Our Gravity Die Casting Operations:

- A356.0 (AlSi7Mg): Excellent castability and corrosion resistance with good strength and ductility

- A319.0 (AlSi5Cu3): Good mechanical properties and pressure tightness

- A514.0 (AlMg3): Superior corrosion resistance, especially in marine environments

- A535.0 (AlMg7): Highest strength among non-heat-treatable alloys

- A413.0 (AlSi12): Exceptional fluidity and resistance to hot cracking

- A380.0 (AlSi8Cu3): Excellent combination of castability and mechanical properties

International Standards Compliance:

- ASTM B26/B26M (Standard Specification for Aluminum-Alloy Sand Castings)

- ASTM B108/B108M (Standard Specification for Aluminum-Alloy Permanent Mold Castings)

- IS 617 (Aluminum and Aluminum Alloy Ingots and Castings for General Engineering Purposes)

- EN 1706 (Aluminum and Aluminum Alloys – Castings – Chemical Composition and Mechanical Properties)

- JIS H5302 (Aluminum Alloy Castings)

- DIN EN 1676 (Aluminum and Aluminum Alloys – Alloyed Ingots for Remelting)

Material Properties

| Property | A356.0 (AlSi7Mg) | A319.0 (AlSi5Cu3) | A413.0 (AlSi12) | A514.0 (AlMg3) |

|---|---|---|---|---|

| Tensile Strength (MPa) | 230-280 | 180-240 | 170-200 | 170-220 |

| Yield Strength (MPa) | 160-220 | 120-170 | 80-120 | 90-130 |

| Elongation (%) | 2-5 | 1.5-3 | 2.5-4 | 3-8 |

| Hardness (Brinell) | 70-90 | 70-85 | 55-75 | 60-75 |

| Density (g/cm³) | 2.67 | 2.79 | 2.66 | 2.65 |

| Thermal Conductivity (W/m·K) | 151 | 109 | 130 | 125 |

| Electrical Conductivity (%IACS) | 39 | 27 | 31 | 29 |

| Modulus of Elasticity (GPa) | 72.4 | 74.5 | 71 | 71.5 |

| Casting Temperature (°C) | 650-750 | 670-760 | 575-650 | 680-780 |

| Heat Treatment | T6, T7 | T5, T6 | Not typically heat treated | Not typically heat treated |

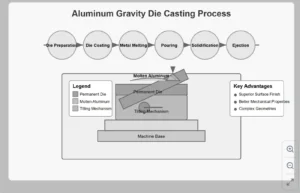

Manufacturing Process

Our Aluminum gravity die casting production follows a meticulously controlled process:

- Design & Engineering: Collaborative development with clients to optimize component design for gravity die casting, including gating system design and solidification simulation using advanced CAD/CAM software and casting simulation tools.

- Pattern & Die Manufacturing: Precision CNC machining of permanent metal molds (typically H13 or H11 tool steel) with carefully engineered cooling channels, venting systems, and draft angles to ensure optimal casting quality.

- Material Selection & Preparation: Raw material is inspected and tested for chemical composition and purity before being charged into the melting furnace.

- Melting & Metal Treatment: Aluminum is melted in electric or gas-fired furnaces under controlled conditions. The melt undergoes degassing, grain refinement, and modification treatments to enhance final casting properties.

- Die Preparation: The permanent mold is preheated to optimal temperature (typically 150-300°C) and coated with specialized refractory die coatings to facilitate easy release and improve surface finish.

- Casting Process: Using our tilting-type gravity casting machines, molten Aluminum is poured into the die cavity at controlled rates to minimize turbulence and entrapped gases. The tilting mechanism ensures smooth, laminar flow of metal.

- Solidification & Cooling: The filled die is allowed to cool for a predetermined time under controlled conditions, often with strategic cooling channels to optimize solidification patterns and minimize shrinkage.

- Ejection & Initial Inspection: Once solidified, the casting is ejected from the mold and undergoes preliminary visual inspection for surface defects.

- Post-Casting Operations: Depending on specifications, castings may undergo:

- Trimming and gate removal

- Heat treatment for enhanced mechanical properties

- Precision machining of critical surfaces

- Surface finishing processes (shot blasting, polishing, painting, anodizing)

- Quality Control: Comprehensive inspection using coordinate measuring machines (CMMs), X-ray analysis, dye penetrant testing, and mechanical property testing ensures compliance with specifications.

Manufacturing Equipment

Our facility employs advanced machinery and technology for consistent, high-quality production:

- Tilting-Type Gravity Die Casting Machines:

- LPM GDC-500: 500kg clamping force with electronic tilt control

- Kurtz AL-13-13: Programmable tilting mechanism with 1300x1300mm die capacity

- DISA DGM-2000: Automated cycle control with 2000kg capacity

- Custom-built specialized machines for larger components

- Melting & Metal Treatment Equipment:

- Medium-frequency induction furnaces (250-1000 kg capacity)

- Resistance crucible furnaces for specialized alloys

- FOSECO SMARTT degassing units with nitrogen purge capability

- Spectro analytical equipment for real-time composition monitoring

- Heat Treatment Facilities:

- Computer-controlled T6 heat treatment furnaces

- Solution treatment, quenching, and aging facilities

- Temperature-controlled cooling systems

- Finishing & Machining Centers:

- CNC machining centers for secondary operations

- Multi-axis CNC systems for complex geometries

- Automated deburring and finishing cells

- Inspection & Testing Equipment:

- Zeiss coordinate measuring machines (CMMs)

- X-ray fluorescence analyzers for material composition verification

- Mechanical testing equipment for tensile, hardness, and impact testing

- Dye penetrant and ultrasonic testing apparatus

Typical Components Produced by Aluminum Gravity Die Casting

Our Aluminum gravity die casting capabilities extend to a wide range of industrial components:

| Industry | Components | Key Features |

|---|---|---|

| Electrical | Junction boxes, Transformer housings, Terminal covers, Heat sinks | Excellent conductivity, EMI shielding, complex cooling fins |

| Power Line Hardware | Cable clamps, Connectors, Strain insulators, Line hardware | Weather resistance, electrical properties, structural integrity |

| Plumbing | Valve bodies, Pump housings, Faucet bodies, Water meter housings | Pressure tight, corrosion resistant, complex internal channels |

| HVAC | Compressor housings, Fan hubs, Diffuser frames, Evaporator components | Dimensional stability, thermal properties, air/water tight |

| Fluid Control | Valve bodies, Impeller housings, Flow meters, Pressure regulators | Leak-proof designs, precision internal passages, corrosion resistance |

| Automotive | Intake manifolds, Oil pans, Transmission cases, Brackets | Weight reduction, strength, temperature resistance |

| Industrial Machinery | Gear housings, Motor mounts, Bearing housings, Frames | Precision mounting surfaces, vibration dampening, structural integrity |

| Lighting | Light housings, Heat sinks, Reflector bases, Fixture mounts | Thermal management, aesthetic finish, corrosion resistance |

Surface Finishing Options

We offer various surface treatments and finishes to enhance performance and aesthetics:

| Finish Type | Process | Benefits | Applications |

|---|---|---|---|

| Natural Cast | Light blasting or tumbling | Economical, maintains dimensional accuracy | Internal components, structural parts |

| Shot Blasting | Projection of steel or glass media | Uniform matte finish, stress relief | General industrial components |

| Polishing | Mechanical or vibratory techniques | Smooth reflective surface, improved corrosion resistance | Decorative parts, fluid flow components |

| Anodizing | Type I, II or III electrolytic oxidation | Enhanced surface hardness, corrosion resistance, color options | Architectural, marine, outdoor applications |

| Powder Coating | Electrostatic application of dry powder | Durable, wide color range, excellent corrosion protection | External components, electrical enclosures |

| Wet Painting | Spray application of liquid coatings | Custom colors, specialized properties | Decorative and branded components |

| Chemical Conversion | Chromate or chrome-free treatments | Improved paint adhesion, corrosion resistance | Substrate for further finishing |

| Impregnation | Resin infiltration under vacuum | Seals microporosity, ensures pressure tightness | Hydraulic components, pressure vessels |

Dimensional Specifications & Tolerances

Our gravity die casting process provides superior dimensional accuracy compared to sand casting:

| Dimension | Standard Tolerance | Precision Tolerance (with additional machining) |

|---|---|---|

| Up to 50mm | ±0.25mm | ±0.10mm |

| 51-150mm | ±0.35mm | ±0.15mm |

| 151-300mm | ±0.50mm | ±0.20mm |

| 301-500mm | ±0.65mm | ±0.30mm |

| >500mm | ±0.80mm | ±0.40mm |

| Flatness (per 100mm) | 0.3mm | 0.15mm |

| Straightness (per 100mm) | 0.3mm | 0.15mm |

| Wall Thickness Minimum | 3.0mm | 2.5mm |

| Draft Angle (external) | 1-3° | 0.5-1° (with special tooling) |

| Draft Angle (internal) | 2-3° | 1-2° (with special tooling) |

| Surface Roughness (Ra) | 3.2-6.4μm | 1.6-3.2μm |

Performance Metrics

| Performance Parameter | Specification | Testing Method |

|---|---|---|

| Pressure Tightness | Hydraulic: Up to 30 bar<br>Pneumatic: Up to 15 bar | Hydrostatic testing, Helium leak detection |

| Heat Resistance | Continuous: -40°C to 200°C<br>Intermittent: Up to 250°C | Thermal cycling, Heat soak testing |

| Corrosion Resistance | Salt spray test: 250-1000 hours<br>(depending on alloy and treatment) | ASTM B117 Salt Spray Testing |

| Impact Strength | 30-80% of wrought counterparts | Charpy impact testing |

| Fatigue Strength | 65-85% of wrought counterparts | Rotating beam testing |

| Electrical Conductivity | 25-40% IACS (varies by alloy) | Eddy current testing |

| EMI Shielding | 60-75 dB attenuation | Shielding effectiveness testing |

| Dimensional Stability | <0.1% change over 5 years | Long-term measurement studies |

| Vibration Dampening | 2-3x better than comparable steel components | Resonance testing |

| Weight Reduction | 60-70% lighter than cast iron equivalents | Comparative analysis |

Industries Served

Our Aluminum gravity die cast parts are utilized across diverse industries:

- Electrical & Electronics: Enclosures, heat sinks, connection boxes, transformer components, Aluminum Hotline clamps, Aluminum Transformer Connectors and Spade terminals, Aluminum Mechanical Connectors, Z Bar connectors

- Power Transmission: Cable connectors, clamps, Aluminum Powerline hardware and Aluminum Powerline clamps, Liveline clamps hardware for power lines

- Plumbing & Water Management: Valve bodies, pump components, faucet housings, water meters

- HVAC & Refrigeration: Compressor housings, fan components, heat exchangers

- Automotive: Engine components, transmission parts, brackets, decorative trim

- Industrial Equipment: Motor housings, gear boxes, pneumatic components

- Lighting: Fixture housings, heat dissipation components, structural elements

- Renewable Energy: Solar mounting structures, wind power components

- Medical Equipment: Equipment housings, structural components for non-implant applications

- Consumer Goods: Durable goods components, appliance parts, furniture hardware

Our Competitive Advantages

Technical Excellence

- Advanced Die Design: Our in-house tooling department utilizes computational fluid dynamics and solidification simulation software to optimize die designs for superior casting quality.

- Metallurgical Expertise: Our team of metallurgists ensures optimal alloy selection and melt treatment for each application.

- Process Control: Automated monitoring systems track critical parameters throughout the casting process, ensuring consistency across production runs.

- Vertical Integration: From alloy formulation to finishing operations, we maintain control over the entire manufacturing process.

Manufacturing Capabilities

- Component Size Range: From small precision parts (50g) to large industrial components (up to 20kg).

- Production Volumes: Flexibility to handle both high-volume production runs and smaller specialized orders.

- Complex Geometries: Ability to cast components with internal passages, undercuts, and complex structural features.

- Multi-material Solutions: Capability to incorporate brass inserts, steel reinforcements, or other materials into the casting process.

Quality Assurance

- ISO 9001:2015 Certified: Comprehensive quality management system ensuring consistent procedures and documentation.

- Material Certification: Detailed material test reports (MTRs) provided for all production batches.

- 100% Inspection: Critical dimensions and features undergo comprehensive verification.

- Advanced Testing: Non-destructive testing including X-ray, dye penetrant, and ultrasonic inspection where required.

- Traceability: Complete batch traceability from raw material to finished component.

Customer-Focused Approach

- Design Collaboration: Our engineering team works closely with clients to optimize designs for gravity die casting.

- Prototype Development: Rapid prototyping services to validate design concepts before full production.

- Flexible Production Scheduling: Ability to accommodate urgent orders and adjust production priorities.

- Technical Support: Comprehensive documentation and technical assistance throughout the product lifecycle.

- Value-Added Services: Secondary machining, assembly, testing, and customized packaging options.

Turnaround Time

- Standard Production: 4-6 weeks from order confirmation for established products

- New Product Development: 6-10 weeks including tooling design and manufacturing

- Prototype Development: 2-3 weeks for rapid prototypes using existing similar tooling

- Rush Orders: Expedited service available at premium pricing for urgent requirements

- Sample Development: 1-2 weeks for existing products

Packaging and Shipping

We provide comprehensive packaging solutions to ensure your components arrive in perfect condition:

- Standard Packaging: Individual VCI (Volatile Corrosion Inhibitor) wrapping, foam separation, and sturdy corrugated cartons

- Premium Options: Custom wooden crates, vacuum-sealed packaging, reusable containers

- Bulk Packaging: Pallet loads with appropriate separation and protection

- Custom Labeling: Company logo, part numbers, barcodes, and specifications printed on packaging

- Documentation: Comprehensive commercial documentation including packing lists, material certifications, inspection reports

- Export Preparation: All shipments comply with international shipping regulations and export documentation

- Shipping Methods: Sea freight (standard), air freight (expedited), courier services (samples)

- Packaging Engineering: Custom designs for components with special handling requirements

Frequently Asked Questions

Q: What is the difference between gravity die casting and high-pressure die casting?

A: Gravity die casting relies on gravity to fill the mold rather than high pressure. This results in castings with lower porosity, better mechanical properties, and the ability to be heat treated. It’s ideal for components requiring pressure tightness, higher strength, and the ability to be welded.

Q: What wall thickness can be achieved with your gravity die casting process?

A: Our standard gravity die casting process can achieve wall thicknesses ranging from 3mm to 25mm, compared to high-pressure die casting which typically handles thinner walls (0.5-3mm). The thicker walls possible with gravity die casting often result in more robust components with better structural integrity for certain applications.

Q: Can Aluminum gravity die cast parts be heat-treated?

A: Yes, unlike high-pressure die cast parts which often contain entrapped gases that cause blistering during heat treatment, gravity die cast components can undergo various heat treatments including T6 strengthening treatments. This allows for significant enhancement of mechanical properties such as tensile strength and hardness.