Back Nuts

Back Nuts

We are one of the leading manufacturers and exporters of Brass Back Nuts from India. We have been supplying premium-quality Back Nuts to the world market for many decades. Brass Back Nuts are essential components used in plumbing and pipe fitting applications, particularly for securing taps, valves, and other fixtures to sinks and panels. These internally threaded hexagonal nuts offer superior strength, corrosion resistance, and machinability, making them ideal for both domestic and industrial usage.

We are one of the leading manufacturers and exporters of Brass Back Nuts from India. We have been supplying premium-quality Back Nuts to the world market for many decades. Brass Back Nuts are essential components used in plumbing and pipe fitting applications, particularly for securing taps, valves, and other fixtures to sinks and panels. These internally threaded hexagonal nuts offer superior strength, corrosion resistance, and machinability, making them ideal for both domestic and industrial usage.

Our Back Nuts are widely appreciated for their dimensional accuracy, consistent performance, and long-lasting durability. We offer customization in sizes, threads, material grades, and finishes to meet specific requirements. With a global customer base across the USA, Europe, the Middle East, and Africa, we understand and comply with international standards like BS 864, IS 319, ASTM B16, and DIN 8076. These Back Nuts are available in both standard and custom-made designs for OEM applications.

Material Grades

Brass Back Nuts can be manufactured in various Brass compositions depending on usage, pressure tolerance, and environmental exposure. The typical grades include:

| Material Type | Composition Standard | Key Elements | Properties |

|---|---|---|---|

| Free Cutting Brass | IS 319 Type I | Cu: 57-63%, Pb: 2.0-3.0%, Zn: R | High machinability, good strength |

| High Tensile Brass | IS 320 | Cu: 55-59%, Pb: 1.0%, Fe: 0.5% | Higher strength, tougher |

| DZR Brass | BS EN 12165 CW602N | Cu: 61%, Zn: Balance, As: 0.1% | Dezincification resistant, durable |

| Lead-Free Brass | ASTM B584 | Cu: 85-89%, Bi: 2.0%, Zn: R | Safe for potable water systems |

Manufacturing Processes

Brass Back Nuts are manufactured through a combination of hot forging, precision CNC machining, threading, and finishing. The manufacturing process includes:

Raw Brass Rod procurement and cutting

Hot forging or casting for blank formation

CNC Turning and Threading (metric, BSP, NPT)

Chamfering, Deburring, and Quality Check

Surface treatment (Natural, Nickel, Chrome)

Custom labeling and packaging

Machinery Used

CNC Lathes (Fanuc, Siemens controlled)

Hot Forging Press (Hydraulic and Mechanical)

Thread Rolling Machines

Surface Polishing Units

Automated Inspection Systems

Typical Parts Produced

Hexagonal Back Nuts

Round Back Nuts with Lugs

Dome Type Nuts

Slotted Panel Nuts

Lock Nuts for Compression Fittings

Finish Options

Natural Brass Finish

Nickel Plated

Chrome Plated

Antique Brass

Electropolished

Industries Using Brass Back Nuts

Plumbing and Sanitation

HVAC and Water Distribution

Gas Fitting and Metering

Marine and Shipbuilding

Renewable Energy (Solar Mounting)

OEM Manufacturing (Appliances and Valves)

Tolerances

Our Back Nuts comply with close dimensional tolerances:

| Parameter | Tolerance (mm) |

|---|---|

| Outer Diameter | ± 0.10 mm |

| Thread Pitch Accuracy | Class A as per BS/ISO |

| Hex Across Flats | ± 0.15 mm |

| Thickness | ± 0.20 mm |

Performance Metrics

Thread Strength Tested (up to 15 bar)

Salt Spray Resistance (Nickel Plated > 96 hours)

Torque Resistance (Standard > 20 Nm)

Thermal Endurance: Up to 120°C

Lifespan: 15+ Years under normal usage

Turnaround Time

We offer a standard turnaround time of 4-6 weeks including production, inspection, and customized packaging.

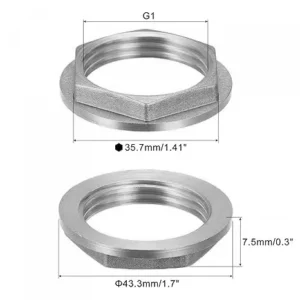

Size – Dimensional Chart (Metric & BSP Threads)

| Size (Thread) | Outer Diameter (mm) | Thickness (mm) | Across Flats (mm) | Type |

|---|---|---|---|---|

| 1/2″ BSP | 26.4 | 4.5 | 24 | Hex |

| 3/4″ BSP | 32.9 | 5.0 | 30 | Hex |

| 1″ BSP | 41.9 | 6.0 | 38 | Hex |

| 1.1/4″ BSP | 50.8 | 6.5 | 46 | Hex |

| Custom Sizes | On Request | As required | Custom | Hex/Dome |

Why Choose Us?

Faster Turnaround: With efficient production and inventory management, we ensure quicker deliveries.

Customized Solutions: Tailored Back Nuts with personalized labeling and packaging.

Global Experience: Over 30 years of export expertise serving USA, UK, EU, and Middle East clients.

Customer Support: Prompt, clear communication and technical guidance.

Flexible Manufacturing: We handle both small batch and high-volume orders.

Compliance: We meet BS, IS, ASTM, and DIN standards ensuring global compatibility.

Packaging & Shipping

All Back Nuts are cleaned, dried, and packed with utmost care:

Polybag + Corrugated Box + Palletized Export Carton

Customer labels/barcodes included

Fumigated wooden crates for sea shipments

Air-freight packaging options available

Customer Testimonial

John Mathews – Ohio, USA

“We’ve been sourcing Brass Back Nuts from this supplier in India for over 7 years. Their quality, consistency, and commitment are exceptional. Timely deliveries, solid technical understanding, and the flexibility to meet our special requests keep us coming back. Highly recommended!”

Typical Q & A

Q: Can you supply Back Nuts with BSPT threads?

A: Yes, we manufacture BSP, BSPT, NPT, and Metric threads.Q: What is your MOQ for Back Nuts?

A: Our MOQ starts from 5,000 pieces, but we also support trial runs for new clients.Q: Are these Back Nuts safe for drinking water use?

A: Yes, we offer Lead-Free and DZR Brass compliant with potable water standards.Q: Do you offer third-party inspection?

A: Yes, we welcome inspection by SGS, TUV, or your preferred agency.Q: Can you laser engrave our logo?

A: Absolutely, logo engraving or stamping can be done.Q: What’s your lead time for repeat orders?

A: Typically 4 weeks, subject to volume and finish.Q: Do you export to the USA?

A: Yes, we have long-term customers in the USA and comply with ASTM standards.Q: Can I get a few samples before order?

A: Yes, samples are provided against courier charges or with order confirmation.Q: Are these suitable for solar applications?

A: Yes, we supply corrosion-resistant Brass Back Nuts for solar panel mounting systems.Q: Do you have ROHS compliant versions?

A: Yes, we offer ROHS & REACH-compliant Back Nuts for European markets.

Glossary of Terms

BSP: British Standard Pipe thread

NPT: National Pipe Thread (US Standard)

DZR Brass: Dezincification Resistant Brass suitable for aggressive water conditions

CNC Machining: Computer Numerical Control based precision machining

Electropolishing: Electrochemical process for polishing metal surfaces

Looking for reliable Brass Back Nut suppliers?

Request a quote today, email us for a product brochure, or contact us via WhatsApp or phone for expert assistance. We’re here to serve your custom requirements with precision and speed.