Brass Press Lock Type Inserts

Brass Press Lock Type Inserts

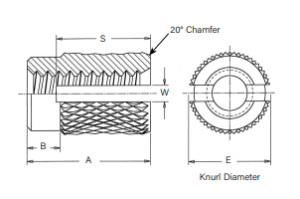

| Brass Press Lock Type Inserts Datasheet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Type | Thread Code (1) | Length Code | A ±0.005 | E Nom. | B ±0.015 | S Nom. | W ±0.015 | Hole Size in Material | ||

| Aluminum | Brass | Min. Hole Depth | Hole Dia. + .002 | ||||||||

| .086-56 (#2-56) | PPA | PPB | 256 | 1 | 0.156 | 0.134 | 0.04 | 0.115 | 0.02 | 0.196 | 0.125 |

| .112-40 (#4-40) | PPA | PPB | 440 | 1 | 0.188 | 0.169 | 0.045 | 0.14 | 0.02 | 0.228 | 0.156 |

| 2 | 250 | 0.06 | 0.19 | 0.29 | |||||||

| .138-32 (#6-32) | PPA | PPB | 632 | 1 | 0.25 | 0.2 | 0.06 | 0.19 | 0.031 | 0.29 | 0.188 |

| 2 | 0.313 | 0.075 | 0.235 | 0.353 | |||||||

| .164-32 (#8-32) | PPA | PPB | 832 | 1 | 0.25 | 0.231 | 0.06 | 0.19 | 0.047 | 0.29 | 0.219 |

| 2 | 0.313 | 0.075 | 0.235 | 0.353 | |||||||

| .190-24 (#10-24) | PPA | PPB | 24 | 2 | 0.375 | 0.263 | 0.09 | 0.28 | 0.062 | 0.415 | 0.25 |

| .190-32 (#10-32) | PPA | PPB | 32 | 1 | 0.313 | 0.263 | 0.075 | 0.235 | 0.062 | 0.353 | 0.25 |

| 2 | 0.375 | 0.09 | 0.28 | 0.415 | |||||||

| 250-20 (1/4-20) | PPA | PPB | 420 | 1 | 0.438 | 0.332 | 0.105 | 0.33 | 0.078 | 0.478 | 0.313 |

| 2 | 0.5 | 0.12 | 0.375 | 0.54 | |||||||

Brass Press Lock Type Inserts are an innovative type of press-fit expansion insert designed specifically for thermoplastic molding applications. Manufactured by Conex Metals, these brass inserts incorporate a unique self-locking design that ensures a secure, low-torque installation with a permanent, leak-proof connection. Produced with precision and high-quality brass, our inserts offer exceptional durability and reliability, making them a trusted choice for various industrial and engineering applications.

Key Features of Press Lock Type Inserts

Self-Locking Expansion Mechanism:

The press lock design allows the insert to expand upon installation, engaging securely with the molded material. This locking action minimizes the required screw installation torque and enhances the stability of the threaded connection.Material & Corrosion Resistance:

Made from high-quality brass, these inserts offer excellent corrosion resistance and long-term durability in various environmental conditions. They are ideally suited for use in water and gas applications in thermoplastic components.Low Installation Torque:

The design ensures that minimal force is needed to achieve a secure connection. This is particularly beneficial in thermoplastic molding, where excessive torque can damage the surrounding material.Permanent and Leak-Proof:

Once pressed into place, the insert forms a permanent threaded connection that cannot be disassembled, ensuring reliable performance over the product’s lifespan.

Technical Specifications (Example)

| Parameter | Specification (Typical) |

|---|---|

| Material | Brass (e.g., UNS CA‑360) |

| Thread Sizes Available | Ranges typically from M3 to M12 (custom options available) |

| Design | Press-fit, expansion type with self-locking feature |

| Installation Torque | Very low; designed to minimize stress on thermoplastic components |

| Application | Thermoplastic molding for water, gas, and other fluid systems |

| Finish | Natural polished brass |

*Note: Specific dimensions and thread pitches can be customized based on application requirements.

Applications of Press Lock Type Inserts

Thermoplastic Molding:

Used in injection molding processes to embed a durable metal thread into plastic parts, ensuring robust and long-lasting threaded connections.Plumbing & Gas Systems:

Ideal for creating reliable, leak-proof joints in thermoplastic water and gas fittings, where low torque and permanent assembly are critical.Consumer Electronics & Appliances:

Provides a secure fastening solution for components that require precise and durable threaded connections without compromising the integrity of the plastic part.

Advantages

Enhanced Security:

The self-locking design ensures that the insert remains firmly in place, providing a permanent and tamper-proof connection.Cost Efficiency:

Integrates seamlessly into the manufacturing process, eliminating the need for secondary assembly steps and reducing production costs.Improved Performance:

Delivers consistent thread quality and minimizes the risk of leaks, even under varying environmental conditions.Versatility:

Available in a range of sizes and thread specifications to meet diverse application needs in various industries.

By choosing Conex Metals’ Press Lock Type Inserts, you invest in a reliable, high-performance solution that enhances the durability and integrity of thermoplastic molded components, ensuring optimal functionality and long-term performance.