Bronze Ground Rod-U-clamps | Bronze-Guv-Clamps

Bronze Ground Rod-U-clamps | Bronze-Guv-Clamps

Conex Metals is a distinguished name in the field of electrical grounding solutions, offering an advanced range of Bronze Ground Rod U Clamps and Bronze GUV Ground Clamps crafted with engineering excellence in India. With over 30 years of industry experience, we specialize in delivering high-performance grounding products that meet the rigorous demands of electrical and infrastructure projects worldwide.

Our Ground Rod U Clamps are meticulously produced using CDA 955 Aluminium Bronze for the clamp body and Silicon Bronze for all fastening components such as nuts, washers, and bolts. These materials are selected to deliver outstanding strength, electrical conductivity, and corrosion resistance, making them ideal for long-term performance even in aggressive environments.

Designed for reliability in industrial, commercial, and residential grounding systems, each clamp ensures a secure and stable connection to the ground rod. We manufacture in compliance with international standards like ASTM, BS, DIN, IS, and JIS, guaranteeing global compatibility and unmatched quality.

Backed by decades of global exposure, Conex Metals is a preferred supplier for electrical utilities, contractors, and civil infrastructure developers seeking dependable earthing hardware. Our clamps are engineered not just to meet expectations-but to exceed them.

Bronze Ground Rod U Clamps

Conex Metals Bronze Ground Rod U Clamps are engineered for high-reliability grounding applications where secure, low-resistance electrical connections are essential. Featuring a durable CDA 955 Aluminium Bronze body paired with Silicon Bronze hardware, these clamps are designed to ensure efficient performance in demanding environments. Their U-bolt configuration provides a strong mechanical grip around standard ground rods while maximizing the electrical contact area for superior conductivity.

Utilizing precision casting and CNC machining, each clamp is manufactured to tight dimensional tolerances, ensuring repeatable performance across large production runs. The Aluminium Bronze alloy, with its high Aluminium content (~11–13%), imparts excellent strength, corrosion resistance, and electrical performance. Meanwhile, the Silicon Bronze fasteners (nuts, bolts, and washers) are purposefully selected to minimize galvanic interactions and guarantee long-term structural and electrical integrity.

These clamps are ideal for grounding systems in utilities, substations, industrial complexes, and commercial installations, where failure is not an option. Their corrosion resistance and mechanical strength make them suitable for both indoor and outdoor use, even in chemically aggressive or coastal environments.

Bronze GUV Ground Clamps – Technical Specifications

Bronze GUV Ground Clamps are specifically designed for ground-to-metallic-structure connections, making them indispensable in cathodic protection systems, underground utility grounding, and tank or pipeline earthing applications. The GUV type clamp connects conductors to buried conductive surfaces such as tanks, vessels, or pipelines.

- Body Material: CDA 955 Aluminium Bronze

– Composition: ~89% Copper, 11% Aluminium with trace Iron/Nickel

– Features: High mechanical strength, excellent conductivity, and resistance to corrosion in underground conditions. - Hardware: Silicon Bronze

– ASTM B98 compliant

– Composition: ~96% Copper, ~4% Silicon

– Chosen for superior durability, thread strength, and compatibility with Aluminium bronze bodies.

Each clamp is rigorously tested to meet international grounding and bonding standards, including IEEE 80, NEMA CC 1, and IEC 62561, ensuring safe and effective performance under all conditions.

Ground Rod U Clamp Production Process- Precision Manufacturing

At Conex Metals, our Ground Rod U Clamps are manufactured in a modern facility that combines metallurgical expertise with advanced machinery. The production process is built around quality, consistency, and international compliance:

- Material Processing:

– CDA 955 alloy is melted in electric induction furnaces for controlled purity.

– Solution heat-treated at 900°C, aged at 625°C for optimal strength and microstructure. - Machining & Finishing:

– Precision CNC machining ensures exact dimensions and surface finish.

– Every clamp is inspected with CMM and optical measurement systems for strict tolerance control. - Hardware Fabrication:

– Silicon Bronze components are formed through cold heading and thread rolling, followed by annealing to relieve internal stress and prevent fatigue.

This tightly controlled process ensures that each clamp not only meets but exceeds industry expectations for performance, durability, and safety in critical grounding applications.

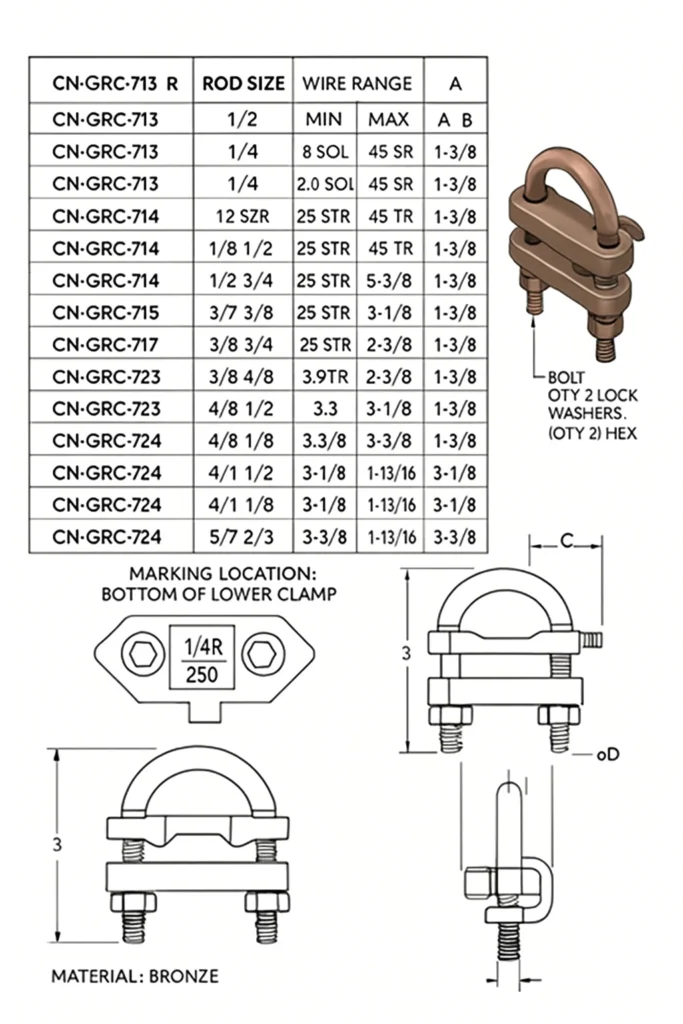

Bronze Ground Rod U Clamps – Standard Sizes and Dimensions

Our range of Bronze Ground Rod U Clamps is available in multiple sizes to suit different conductor and rod specifications. Each clamp is precisely machined to ensure proper fit, excellent electrical contact, and easy installation.

| Model | Ground Rod Diameter (mm) | Conductor Range (AWG) | Length (mm) | Width (mm) | Height (mm) | Bolt Size | Weight (kg) |

| CN-GRC-12 | 12.7 (1/2″) | 6 AWG – 2/0 AWG | 85 | 45 | 35 | M8 × 40 | 0.28 |

| CN-GRC-16 | 15.9 (5/8″) | 4 AWG – 3/0 AWG | 95 | 50 | 40 | M10 × 45 | 0.35 |

| CN-GRC-20 | 19.1 (3/4″) | 2 AWG – 4/0 AWG | 110 | 60 | 45 | M12 × 50 | 0.48 |

| CN-GRC-25 | 25.4 (1″) | 1/0 AWG – 500 MCM | 130 | 70 | 55 | M14 × 60 | 0.65 |

Material Compatibility & Global Equivalents

The main body of our U clamps is made from CDA 955 Aluminium Bronze, a premium alloy recognized globally for its combination of high mechanical strength, corrosion resistance, and excellent conductivity. This alloy corresponds to several international standards, ensuring ease of specification and approval across global markets.

Equivalent International Grades – CDA 955 Aluminium Bronze

| Standard | Grade Designation | Composition | Key Attributes |

| ASTM (USA) | C95500 (CDA 955) | Cu-11Al-4Fe-4Ni | Excellent strength and corrosion resistance |

| BS (UK) | CZ112 | Cu-11Al-4Fe-4Ni | Marine-grade durability |

| DIN (Germany) | CuAl11Fe4Ni4 | Cu-11Al-4Fe-4Ni | High mechanical performance |

| JIS (Japan) | CAC406 | Cu-11Al-4Fe-4Ni | Reliable cast Aluminium bronze |

| IS (India) | Cu-Al11Fe4Ni4 | Cu-11Al-4Fe-4Ni | Suitable for high-stress applications |

| GB (China) | QAl11-6-6 | Cu-11Al-6Fe-6Ni | Heavy-duty bronze casting |

Silicon Bronze Hardware – Material Insights

Our fastening components—nuts, bolts, washers—are made from Silicon Bronze, a copper-based alloy optimized for mechanical durability and corrosion resistance. This material is well-suited for grounding use where moderate conductivity and high mechanical integrity are required.

- Specification: ASTM B98

- Composition: ~96% Copper, ~4% Silicon

- Tensile Strength: 380–480 MPa

- Yield Strength: 170–310 MPa

- Elongation: 50–65%

- Electrical Conductivity: ~18% IACS

Advanced Production Technology & Infrastructure

We leverage modern foundry techniques, high-precision equipment, and robust quality assurance to deliver clamps that meet the strictest performance standards.

- Casting: Investment casting using advanced ceramic shell molds ensures a smooth finish and excellent dimensional accuracy.

- Melting: Performed in electric induction furnaces for precise temperature and alloy control.

- Machining: State-of-the-art 5-axis CNC centers and horizontal mills are employed for final shaping.

- Heat Treatment: Controlled atmosphere furnaces help optimize metallurgical strength and hardness.

- Quality Checks: Optical emission spectrometry, UTM testing, hardness analysis, and dimensional inspection tools ensure compliance.

Manufacturing Workflow and Equipment Overview

| Process | Machinery Used | Process Specs | Inspection & QC |

| Melting & Casting | Electric Induction Furnaces | Max 1650°C, ±5°C thermal precision | Spectro analysis, alloy consistency check |

| Heat Treatment | Atmosphere-Controlled Furnaces | 900°C solution, 625°C age hardening | Hardness test, grain structure inspection |

| CNC Precision Machining | 5-Axis CNC Centers | Tolerance ±0.05mm | CMM, surface quality inspection |

| Thread Rolling | CNC Thread Rolling Machines | Class 6g thread accuracy | Thread profile, pitch verification |

| Surface Finishing | Robotic Polishing Systems | Target finish: Ra ≤ 1.6μm | Roughness meter, visual inspection |

Performance Testing & Validation

All our U Clamps undergo strict performance testing based on global standards for grounding, electrical integrity, and material durability. This ensures long-term serviceability in both standard and extreme environmental conditions.

Certified Test Results

| Test | Standard / Method | Requirement | Typical Performance |

| Electrical Contact Resistance | IEEE 80 | ≤ 5 microhms | 2.8 microhms |

| Ultimate Tensile Strength | ASTM B557 | > 620 MPa | 680 MPa |

| Yield Strength | ASTM B557 | > 270 MPa | 295 MPa |

| Hardness | ASTM E18 (HRB) | 85–95 HRB | 90 HRB |

| Corrosion Resistance (Salt Spray) | ASTM B117 | < 5 μm/year | 2.1 μm/year |

| Current-Carrying Compliance | IEC 62561-2 | Meets/Exceeds standard | Conforms/Exceeds |

Trusted Worldwide for Over 30 Years

- 3 Decades of Manufacturing Excellence

- 8% Customer Quality Rating

- Exported to 50+ Countries

- CDA 955 & ASTM B98 Compliant

- Suitable for Critical Grounding & Lightning Protection Systems

Industries Served & Application Areas

Bronze Ground Rod U Clamps are integral components in safety-critical electrical systems across a wide range of industries. Their primary role is to ensure a secure, low-resistance bond between conductors and ground rods, which is vital for fault current dissipation, surge protection, and regulatory compliance.

Key Application Segments:

- Power Generation & Distribution: Widely used in transmission lines, substations, and switchyards for effective earthing.

- Telecommunications: Deployed in telecom towers, data centers, and network installations to safeguard against lightning and electromagnetic interference.

- Industrial Environments: Common in oil refineries, chemical plants, mining operations, and manufacturing units for static discharge and personnel protection.

- Construction & Infrastructure: Installed in commercial and residential buildings to meet electrical safety code requirements.

- Cathodic Protection Systems: Used in grounding applications for underground pipelines, fuel storage tanks, and coastal/marine installations where corrosion resistance is essential.

Precision Quality Control & Tolerances

Our production process integrates stringent quality assurance protocols to guarantee dimensional precision and structural integrity of every clamp.

Standard Tolerances & Surface Quality:

- Linear Dimensions:

– Up to 50mm: ±0.05mm

– 50–100mm: ±0.1mm

– Above 100mm: ±0.15mm - Thread Accuracy:

– External: ISO 965 Class 6g

– Internal: ISO 965 Class 6H

– Pitch tolerance: ±0.02mm - Surface Roughness:

– Machined surfaces: Ra ≤ 1.6μm

– Cast surfaces: Ra ≤ 3.2μm - Geometric Features:

– Flatness, perpendicularity, and straightness within 0.05mm

– Angular accuracy: ±0.5°

Production Turnaround & Output Capacity

We maintain optimized production workflows and material inventories to deliver consistent lead times for both standard and custom configurations.

- Standard Lead Time: 4–6 weeks from order confirmation

- Expedited Delivery: 2–3 weeks for urgent orders (standard models)

- Custom Orders: 6–8 weeks depending on technical complexity

- Monthly Output Capacity: 10,000+ clamps, scalable for high-volume or seasonal demand

Frequently Asked Questions (FAQs)

Q1: What distinguishes CDA 955 Aluminium Bronze from regular bronze?

A1: CDA 955 contains approx. 11% Aluminium, delivering more than double the tensile strength of standard bronze, with excellent corrosion resistance and wear characteristics. It’s especially suited for harsh environments and buried installations.

Q2: Why use Silicon Bronze for fasteners instead of stainless steel?

A2: Silicon Bronze prevents galvanic corrosion when mated with Aluminium Bronze, ensuring electrochemical compatibility. It offers excellent durability and conductivity, which stainless steel lacks in grounding roles.

Q3: What current capacity do different models support?

A3:

- GRC-12: ~95A

- GRC-16: ~130A

- GRC-20: ~180A

- GRC-25: ~260A

These are based on 30°C ambient and NEC conductor guidelines.

Q4: Are these clamps suitable for coastal or marine areas?

A4: Absolutely. CDA 955’s saltwater resistance makes it ideal for marine use. Our clamps consistently pass ASTM B117 salt spray testing with <5μm/year corrosion rate.

Q5: What torque should be applied during installation?

A5:

- M8: 15–18 Nm

- M10: 25–30 Nm

- M12: 40–45 Nm

- M14: 60–70 Nm

This ensures proper contact without overstressing components.

Q6: Are these clamps suitable for direct burial in soil?

A6: Yes, they are specifically built for direct burial. CDA 955 offers exceptional resistance to soil corrosion, and all clamps meet IEEE 80 standards.

Q7: What documentation is supplied with orders?

A7: Every shipment includes:

- Material Test Certificates (MTCs)

- Dimensional Inspection Reports

- Mechanical & Electrical Test Results

- International Compliance Declarations (ASTM, IEEE, IEC)

Q8: Can I order clamps in custom sizes or thread patterns?

A8: Yes. We support custom engineering including altered dimensions, non-standard threads, special conductor shapes, and unique mounting formats.

Q9: How do Bronze clamps compare to copper or brass options?

A9:

- Stronger than copper

- More corrosion resistant than brass

- Better suited for buried and outdoor environments

CDA 955 strikes an optimal balance between conductivity and structural performance.

Q10: What is the service life expectancy?

A10:

- Standard Conditions: 50+ years

- Marine/Industrial Conditions: 25–40 years

Bronze’s natural resistance to corrosion ensures dependable long-term use.

Why Conex Metals for Grounding Clamps?

- 30+ Years of Industry Expertise

- High-Capacity, Flexible Production

- Tailored Solutions for Global Markets

- In-House Engineering Support

- Strict Quality Control at Every Stage

Our focus on technical excellence, combined with flexible manufacturing and deep industry knowledge, positions us as a preferred supplier for mission-critical grounding systems across the globe.

We provide:

- Rapid custom configuration

- On-time deliveries

- Expert technical support

- Global logistics coordination

Packaging & International Logistics

Each clamp is packaged to ensure safe transit and long shelf life, even in extreme climates:

- Individual Wrapping: Anti-corrosive paper

- Internal Protection: Custom foam inserts

- Outer Packaging: Moisture-resistant, impact-proof cartons

Customized Options:

- Private-label branding

- Client-specific barcoding

- Custom-sized packing formats

Global Shipping Partners: We coordinate through trusted freight agents and express couriers with full tracking and insurance, providing:

- Commercial Invoices

- Packing Lists

- Material Certifications

- Certificates of Origin

- HS Code Documentation

Material Properties of CDA 955 Aluminium Bronze

CDA 955 Aluminium Bronze is a high-performance copper-based alloy known for its exceptional strength, corrosion resistance, and thermal stability. Below are its key physical characteristics:

| Property | Typical Value | Units | Test Standard |

| Density | 7.6 | g/cm³ | ASTM B311 |

| Melting Range | 1040 – 1080 | °C | DTA Analysis |

| Electrical Conductivity | 13 – 15 | % IACS | ASTM B193 |

| Thermal Conductivity | 71 | W/m·K | ASTM E1225 |

| Thermal Expansion Coefficient | 16.4 | µm/m·K | ASTM E228 |

| Elastic Modulus | 110 | GPa | ASTM E111 |

Glossary of Key Technical Terms

- Aluminium Bronze: A copper alloy group with Aluminium content (typically 5–12%), offering improved strength, wear resistance, and corrosion performance compared to traditional bronze.

- CDA 955: Designation by the Copper Development Association for a high-strength Aluminium bronze alloy (Cu-11Al-4Fe-4Ni) used in demanding industrial and marine-grade applications.

- Silicon Bronze: A copper-based alloy containing ~4% silicon, offering excellent mechanical properties, corrosion resistance, and electrical conductivity. Commonly used for bolts, nuts, and grounding hardware.

- Ground Rod: A conductive electrode, typically copper-clad steel, inserted into the ground to establish an earth connection for electrical safety systems.

- U Clamp: A U-shaped mechanical fastener designed to affix conductors securely to ground rods or similar cylindrical bodies, ensuring solid mechanical and electrical connectivity.

- GUV (Ground-to-Underground-Vessel): A specific grounding method for connecting conductors to buried metallic structures such as tanks, pipelines, or vessels, often used in cathodic protection.

- Galvanic Compatibility: The ability of dissimilar metals to coexist in an electrolyte without excessive galvanic corrosion, which is crucial for the longevity of grounding systems.

- IACS (International Annealed Copper Standard): A benchmark for electrical conductivity, with 100% IACS representing the conductivity of pure annealed copper at 20°C.

Related Industry Search Terms

Professionals and buyers often search for our clamps using terms such as:

Bronze earthing clamps, grounding rod connectors, Aluminium Bronze U clamps, CDA 955 hardware, Silicon Bronze fasteners, heavy-duty grounding clamps, marine earthing solutions, industrial-grade rod clamps, GUV grounding connectors, cathodic protection clamps, and IEC/IEEE compliant clamps.

Technical searches often include:

ASTM B98 specs, CDA 955 material standards, IEC 62561-rated grounding, IEEE 80 substation grounding clamps, Bronze clamps manufacturer India, custom grounding accessories, corrosion-resistant grounding systems, and utility-grade Bronze clamps.

Our Competitive Advantages

We differentiate ourselves through:

- Tailored Solutions: Customizable designs and dimensions to suit client-specific installation environments.

- Efficient Production: Agile manufacturing processes that adapt to small and bulk orders with flexible scheduling.

- Reliable Inventory: Well-managed raw material and finished goods stock to enable timely order fulfillment.

- Branded Packaging Options: Including private labeling, logo printing, and client-specific packaging layouts.

Global Experience

With 30+ years of international operations, we understand diverse market requirements, regulatory conditions, and operational challenges in different regions and industries. This global insight enables us to deliver both standardized and customized grounding solutions effectively.

Technical Support & Engineering Expertise

Our team of seasoned engineers is equipped to:

- Assist with system design and product selection

- Develop custom component drawings

- Resolve complex installation or compatibility challenges

- Offer application-specific recommendations

We invest continuously in product innovation, collaborating with materials research centers and technical institutions to remain at the forefront of grounding technology.

International Certifications & Standards

| Standard | Title | Scope | Compliance |

| ASTM B98 | Silicon Bronze Rods and Bars | Hardware material specification | Fully Compliant |

| IEEE 80 | Safety Guidelines for AC Substation Grounding | Grounding design | Fully Compliant |

| IEC 62561-2 | Lightning Protection Components | Clamp and connector requirements | Fully Compliant |

| NEMA CC 1 | Electrical Substation Connectors | Electrical connection hardware | Fully Compliant |

| IS 3043 | Indian Code of Practice for Earthing | Earthing system specifications | Fully Compliant |

| BS 7430 | British Protective Earthing Guidelines | Earthing installation guidance | Fully Compliant |

| DIN VDE 0141 | German Grounding Systems for Power Installations | Grounding protocols | Fully Compliant |

Environmental Responsibility & Sustainability Practices

We are committed to sustainable manufacturing through:

- High Recyclability: Our bronze products are over 95% recyclable at the end of their lifecycle, supporting circular economy principles.

- Energy-Efficient Operations: Utilizing optimized furnace systems, CNC machining with energy monitoring, and advanced control systems to reduce energy consumption.

- Waste Minimization: Implementing lean practices, reclaiming metal scrap, recycling process water, and reducing packaging waste.

- ISO 14001 Alignment: Our operations follow international environmental management protocols to limit emissions, reduce environmental impact, and optimize resource use.

- Long Service Life: Bronze products designed for extended durability (25–50 years), reducing environmental impact through fewer replacements.

Request a Quote Today

Looking for high-performance Bronze Ground Rod U Clamps?

Let our team at Conex Metals provide you with trusted, engineered grounding solutions backed by three decades of industry expertise.

We’re here to help with:

- Product specifications & selection

- Custom configurations & dimensions

- Technical support for unique applications

- Competitive pricing & lead times

📬 Contact Us:

📧 Email: sales@conexmetals.com – Request detailed brochures, datasheets & pricing.

📞 Call Us: Speak directly with our technical team for expert guidance and fast quotations.

💬 WhatsApp Us: Connect with us instantly for order inquiries and real-time assistance.

Ready to strengthen your grounding system? Reach out today and discover why global clients choose Conex Metals for reliability, quality, and support.