Bronze Machined Casting , Bronze Machined Parts

Bronze Machined Casting , Bronze Machined Parts

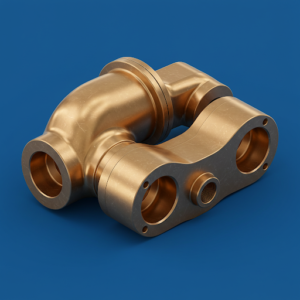

We are one of the leading manufacturers and exporters of Bronze Machined Casting Parts and Bronze Machined Components from Jamnagar, India. We are a leading Bronze casting foundry in India and have been offering Bronze Machining for 3 decades. Our Bronze Machined Parts , Bronze machined components are well accepted around the world. We have been supplying high-quality Bronze Machined Casting Parts, Bronze Machined Parts, Bronze Machined components to the world market for many decades. Our commitment to precision engineering, superior craftsmanship, and adherence to international standards has made us a trusted name in the global market.

We are one of the leading manufacturers and exporters of Bronze Machined Casting Parts and Bronze Machined Components from Jamnagar, India. We are a leading Bronze casting foundry in India and have been offering Bronze Machining for 3 decades. Our Bronze Machined Parts , Bronze machined components are well accepted around the world. We have been supplying high-quality Bronze Machined Casting Parts, Bronze Machined Parts, Bronze Machined components to the world market for many decades. Our commitment to precision engineering, superior craftsmanship, and adherence to international standards has made us a trusted name in the global market.

Whether you need Aluminum Bronze Machined Casting Parts, Silicon Bronze Machined Casting Parts, or Leaded Bronze Machined Castings, we deliver products that meet the highest quality benchmarks. With over three decades of experience, we cater to industries such as automotive, aerospace, marine, and industrial machinery, providing customized solutions tailored to your specific needs.

Whether you need Aluminum Bronze Machined Casting Parts, Silicon Bronze Machined Casting Parts, or Leaded Bronze Machined Castings, we deliver products that meet the highest quality benchmarks. With over three decades of experience, we cater to industries such as automotive, aerospace, marine, and industrial machinery, providing customized solutions tailored to your specific needs.

Material Grades and International Standards

Our Bronze Machined Casting Parts are manufactured using premium-grade materials that comply with international standards such as ASTM, BS, DIN, JIS, and IS. Below are the material grades we specialize in:

Aluminum Bronze Machined Casting Parts

Aluminum Bronze alloys are known for their exceptional strength, corrosion resistance, and wear resistance. We offer the following grades:

- ASTM B148 C95400 (9% Aluminum Bronze)

- ASTM B148 C95500 (11% Aluminum Bronze)

- ASTM B148 C95600 (Nickel-Aluminum Bronze)

- ASTM B148 C95700 (Manganese-Aluminum Bronze)

- ASTM B148 C95800 (Nickel-Aluminum Bronze for Marine Applications)

- ASTM B148 C95900 (Special Aluminum Bronze for High-Strength Applications)

- DIN EN 1982 CB7 (European Standard for Aluminum Bronze)

- BS 1400 AB1 (British Standard for Aluminum Bronze)

Silicon Bronze Machined Casting Parts

Silicon Bronze Machined Casting Parts

Silicon Bronze alloys are valued for their excellent machinability, corrosion resistance, and electrical conductivity. Our offerings include:

- ASTM B505 C87300 (Silicon Bronze for Decorative Applications)

- ASTM B505 C87500 (High-Strength Silicon Bronze)

- ASTM B505 C87600 (Silicon Bronze for Marine Applications)

- ASTM B505 C87800 (Silicon Bronze for Electrical Components)

- DIN EN 1982 CC333G (European Standard for Silicon Bronze)

- JIS H5111 CBC2 (Japanese Standard for Silicon Bronze)

- BS 1400 SCB1 (British Standard for Silicon Bronze)

Phosphor Bronze Machined Casting Components

Phosphor Bronze alloys are renowned for their high fatigue resistance, low friction, and excellent spring properties. We provide:

- ASTM B139 C51000 (Phosphor Bronze for Springs and Bearings)

- ASTM B139 C51100 (Phosphor Bronze for Electrical Contacts)

- ASTM B139 C51900 (High-Strength Phosphor Bronze)

- ASTM B139 C52100 (Nickel-Phosphor Bronze for High-Temperature Applications)

- DIN EN 1982 PB1 (European Standard for Phosphor Bronze)

- JIS H5111 PBC2 (Japanese Standard for Phosphor Bronze)

- BS 1400 PB1 (British Standard for Phosphor Bronze)

Leaded Bronze Machined Castings

Leaded Bronze alloys are ideal for applications requiring low friction and high wear resistance. Our grades include:

- ASTM B584 C93200 (High-Leaded Tin Bronze)

- ASTM B584 C93400 (Medium-Leaded Tin Bronze)

- ASTM B584 C93500 (Low-Leaded Tin Bronze)

- ASTM B584 C93700 (High-Leaded Nickel Bronze)

- ASTM B584 C93800 (Leaded Bronze for Bearings)

- DIN EN 1982 LB1 (European Standard for Leaded Bronze)

- JIS H5111 LBC1 (Japanese Standard for Leaded Bronze)

- BS 1400 LB1 (British Standard for Leaded Bronze)

Lg2 GunMetal Bronze Machined Castings

GunMetal Bronze alloys are widely used in marine and industrial applications due to their excellent corrosion resistance and strength. We offer:

- ASTM B584 LG2 (GunMetal Bronze for Marine Applications)

- ASTM B584 LG4 (High-Strength GunMetal Bronze)

- DIN EN 1982 G-CuSn10Zn (European Standard for GunMetal Bronze)

- BS 1400 LG2 (British Standard for GunMetal Bronze)

- JIS H5111 GBC1 (Japanese Standard for GunMetal Bronze)

Manufacturing Processes and Machinery Used

Our state-of-the-art manufacturing facility is equipped with advanced machinery, including CNC machines, lathes, milling machines, and grinding machines. We employ precision casting techniques such as Sand Casting, Investment Casting, and Centrifugal Casting, followed by meticulous machining to achieve tight tolerances and superior surface finishes. Our processes ensure that every part meets the exact specifications required by our clients.

Typical Parts Produced

We manufacture a wide range of Bronze Machined Casting Parts, including:

- Bushings and Bearings

- Valve Components

- Gears and Sprockets

- Pump Housings

- Marine Propeller Shafts

- Hydraulic Components

Surface Finish and Tolerances

Our parts are available in various surface finishes, including Machined Finish, Polished Finish, and Coated Finish for enhanced corrosion resistance. We maintain tight tolerances of up to ±0.01 mm for critical dimensions, ensuring optimal performance in demanding applications.

Industries We Serve

Our Bronze Machined Casting Parts are widely used in industries such as:

- Automotive: Engine components, transmission parts

- Aerospace: Landing gear components, hydraulic systems

- Marine: Propeller shafts, rudder bearings

- Industrial Machinery: Gears, bushings, and couplings

- Oil and Gas: Valve components, pump parts

Performance Metrics

- Tensile Strength: 300-700 MPa

- Hardness: 60-200 HB

- Corrosion Resistance: Excellent in marine and chemical environments

- Wear Resistance: Ideal for high-friction applications

Turnaround Time

We understand the importance of timely delivery. Our standard turnaround time is 4-6 weeks, with options for expedited production for urgent requirements.

Why Choose Us?

- Global Exposure and Experience: Over 30 years of expertise in manufacturing and exporting Bronze Machined Casting Parts.

- Customization: Ability to produce parts as per your exact specifications.

- Flexibility: Adjustable production timelines to meet your deadlines.

- Quality Assurance: Strict adherence to international standards and rigorous quality checks.

- Customer Support: Dedicated support team for seamless communication and after-sales service.

- Customized Packaging: Packaging with your labels and logos for brand consistency.

Packaging and Shipping

We ensure safe and secure packaging using wooden crates, pallets, or custom packaging as per your requirements. Our logistics partners provide reliable shipping services to destinations worldwide, ensuring timely delivery.

Customer Testimonials

“We have been sourcing Bronze Machined Casting Parts from this company for over five years. Their quality, precision, and customer service are unmatched. Highly recommended!”

- John Smith, USA

Glossary of Terms

- Sand Casting: A casting method using sand molds.

- Investment Casting: A precision casting method using wax patterns.

- CNC Machining: Computer-controlled machining for high precision.

- Tolerance: The permissible limit of variation in a dimension.

- Corrosion Resistance: The ability to withstand degradation due to chemical reactions.

Size-Dimensional Chart

| Part Type | Size Range (mm) | Tolerance (± mm) |

|---|---|---|

| Bushings | 10-500 | 0.01-0.05 |

| Gears | 20-300 | 0.02-0.10 |

| Valve Components | 15-200 | 0.01-0.03 |

| Pump Housings | 50-1000 | 0.05-0.20 |

Typical Q&A Session

- Q: What materials do you use for Bronze Machined Casting Parts?

A: We use Aluminum Bronze, Silicon Bronze, Phosphor Bronze, Leaded Bronze, and Lg2 GunMetal Bronze. - Q: What industries do you cater to?

A: We serve automotive, aerospace, marine, industrial machinery, and oil and gas industries. - Q: What is your turnaround time?

A: Our standard turnaround time is 4-6 weeks. - Q: Do you offer customized packaging?

A: Yes, we provide customized packaging with your labels and logos. - Q: What tolerances can you achieve?

A: We can achieve tolerances of up to ±0.01 mm. - Q: Do you comply with international standards?

A: Yes, we comply with ASTM, BS, DIN, JIS, and IS standards. - Q: Can you handle urgent orders?

A: Yes, we offer expedited production for urgent requirements. - Q: What surface finishes do you offer?

A: We offer machined, polished, and coated finishes. - Q: Do you provide material certifications?

A: Yes, we provide material test certificates with every shipment. - Q: What is your minimum order quantity?

A: We offer flexible MOQs depending on the part complexity and material.

Ready to experience the best in Bronze Machined Casting Parts, Bronze Machining, Bronze parts, Bronze components, Bronze Machined parts and Machined Bronze Components? Contact us today for a quote, request a brochure, or reach out via phone/WhatsApp. Let us help you find the perfect solution for your needs!

Silicon Bronze Machined Casting Parts

Silicon Bronze Machined Casting Parts