Copper Washers

Copper Washers

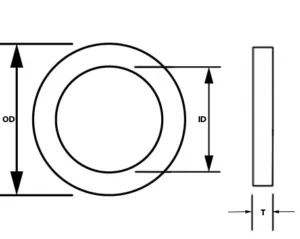

| Copper Washers Datasheet | ||||||

|---|---|---|---|---|---|---|

| Size | USS | SAE | ||||

| Inside Diameter (A) | Outside Diameter (B) | Thickness (C) | Inside Diameter (A) | Outside Diameter (B) | Thickness (C) | |

| #2 | – | – | – | 3/32″ | 1/4″ | 0.020″ |

| #4 | – | – | – | 1/8″ | 5/16″ | 0.032″ |

| #6 | – | – | – | 5/32″ | 3/8″ | 0.049″ |

| #8 | – | – | – | 3/16″ | 7/16″ | 0.049″ |

| #10 | – | – | – | 7/32″ | 1/2″ | 0.049″ |

| #12 | – | – | – | 1/4″ | 9/16″ | 0.065″ |

| 1/4″ | 5/16″ | 0.734″ | 0.065″ | 9/32″ | 5/8″ | 0.065″ |

| 5/16″ | 3/8″ | 7/8″ | 0.083″ | 11/32″ | 11/16″ | 0.065″ |

| 3/8″ | 7/16″ | 1″ | 0.083″ | 13/32″ | 13/16″ | 0.065″ |

| 7/16″ | 1/2″ | 1-1/4″ | 0.083″ | 15/32″ | 15/16″ | 0.065″ |

| 1/2″ | 9/16″ | 1-3/8″ | 0.109″ | 17/32″ | 1-1/16″ | 0.095″ |

| 9/16″ | 5/8″ | 1-15/32″ | 0.109″ | 19/32″ | 1-5/32″ | 0.095″ |

| 5/8″ | 11/16″ | 1-3/4″ | 0.134″ | 21/32″ | 1-5/16″ | 0.095″ |

| 3/4″ | 13/16″ | 2″ | 0.148″ | 13/16″ | 1-15/32″ | 0.134″ |

| 7/8″ | 15/16″ | 2-1/4″ | 0.165″ | 15/16″ | 1-3/4″ | 0.134″ |

| 1″ | 1-1/16″ | 2-1/2″ | 0.165″ | 1-1/16″ | 2″ | 0.134″ |

| 1-1/8″ | 1-1/4″ | 2-3/4″ | 0.165″ | – | – | – |

| 1-1/4″ | 1-3/8″ | 3″ | 0.165″ | – | – | – |

| 1-3/8″ | 1-1/2″ | 3-1/4″ | 0.180″ | – | – | – |

| 1-1/2″ | 1-5/8″ | 3-1/2″ | 0.180″ | – | – | – |

| 1-5/8″ | 1-3/4″ | 3-3/4″ | 0.180″ | – | – | – |

| 1-3/4″ | 1-7/8″ | 4″ | 0.180″ | – | – | – |

| 2″ | 2-1/8″ | 4-1/2″ | 0.213″ | – | – | – |

Copper Washers – Pressed Components are precision‐fabricated parts produced by cold pressing high-quality copper sheet into washer shapes. These components are engineered to provide reliable load distribution, electrical conductivity, and corrosion resistance in a variety of fastening and sealing applications. Manufactured by Conex Metals using advanced pressing techniques and compound dies, they offer consistent dimensions and superior surface finishes suitable for both industrial and decorative uses. With a strong manufacturing base in Jamnagar, India, we supply Copper Washers to some of the most quality-conscious markets worldwide, ensuring excellence in every piece we produce.

Key Features of Copper Washers

Premium Material:

Made from high-quality copper (commonly pure copper or copper alloys), these washers leverage copper’s excellent electrical and thermal conductivity as well as its natural corrosion resistance.Precision Pressing Process:

The components are produced via high-precision pressing techniques that form the washers from copper sheet metal. This process ensures tight tolerances, uniform thickness, and a smooth, polished surface finish.Versatile Size Range:

Copper washers are available in a wide range of inner and outer diameters and thicknesses to match various fastener standards (such as DIN, BS, or custom requirements), ensuring compatibility in different assembly applications.Enhanced Performance:

The design of these pressed components allows for even load distribution across fasteners and provides a robust, durable sealing surface, minimizing the risk of surface damage and improving joint integrity.

Technical Specifications (Example Values)

| Parameter | Specification (Typical) |

|---|---|

| Material Grade | High-quality copper (e.g., C11000) |

| Thickness Range | Typically 0.2 mm to 3.0 mm (customizable) |

| Outer Diameter Range | Standard sizes from approximately 10 mm to 100+ mm |

| Inner Diameter | Designed to match fastener shank sizes (e.g., M4 to M12) |

| Surface Finish | Polished, with options for additional plating or passivation for enhanced corrosion resistance |

| Tolerance | Generally within ±0.005 mm to ±0.02 mm, depending on size and application |

*Note: Exact dimensions and tolerances can be customized based on specific customer requirements.

Applications of Copper Washers

Electrical and Electronics:

Leveraged for their excellent conductivity, these washers are used in circuit assemblies, connectors, and other electronic components.Plumbing and Sealing:

Employed under fasteners in plumbing applications to distribute load and provide a reliable sealing surface.Industrial Machinery:

Used in assemblies where precise load distribution and resistance to wear are critical, ensuring long-term reliability.Decorative Hardware:

Their attractive polished finish makes them suitable for visible assemblies in consumer products and architectural applications.

Advantages of Copper Washers

Superior Conductivity:

Copper’s high electrical and thermal conductivity makes these washers ideal for applications where efficient energy transfer is critical.Corrosion Resistance:

The natural properties of copper, along with optional surface treatments, provide excellent resistance to oxidation and corrosion even in challenging environments.Consistent Quality:

The pressing process guarantees uniformity in dimensions and finish, ensuring repeatable performance in high-volume production.Cost-Effective Production:

Advanced pressing techniques minimize material waste and reduce production costs, offering a competitively priced solution without compromising quality.

By choosing Conex Metals’ Copper Washers – Pressed Components, you invest in precision-engineered parts that enhance the performance, durability, and reliability of your assemblies while offering the aesthetic and functional benefits of copper.