Brass Press Knocked Inserts

Brass Press Knocked Inserts

| Brass Press Knocked Inserts Datasheet | |||||||

|---|---|---|---|---|---|---|---|

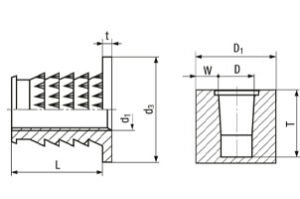

| Thread size d1 | L +0/-0,25 | d3 nom | D min | D1 min | t ±0,15 | W min | T |

| M2,5 | 5,2 | 7,1 | 3,7-4 | 7,4 | 0,75 | 1,7 | 5,3 |

| M2,5 | 4,1 | 7,1 | 3,7-4 | 7,4 | 0,75 | 1,7 | 4,2 |

| M3 | 5,2 | 7,1 | 3,7-4 | 7,4 | 0,75 | 1,7 | 5,3 |

| M3 | 4,1 | 7,1 | 3,7-4 | 7,4 | 0,75 | 1,7 | 4,2 |

| M4 | 8,5 | 8,7 | 5,4-5,9 | 10,9 | 0,75 | 2,5 | 8,6 |

| M4 | 5,6 | 8,7 | 5,4-5,9 | 10,9 | 0,75 | 2,5 | 5,8 |

| M5 | 10,1 | 11,1 | 6-6,5 | 12,2 | 0,9 | 2,85 | 10,2 |

| M5 | 6,6 | 11,1 | 6-6,5 | 12,2 | 0,9 | 2,85 | 6,8 |

| M6 | 12,3 | 12,7 | 7,7-8,2 | 14,6 | 1 | 3,2 | 12,5 |

| M6 | 7,7 | 12,7 | 7,7-8,2 | 14,6 | 1 | 3,2 | 7,9 |

| M8 | 10,1 | 14,3 | 10,2-10,6 | 19,1 | 1,25 | 4,25 | 10,3 |

Brass Press Knocked Inserts are precision-engineered threaded inserts manufactured by Conex Metals using a press-knocking process. This method involves cold-forging the insert to achieve an exact, consistent thread profile, making them ideally suited for applications where conventional tapping or machining may damage softer materials. These inserts are typically made from high-quality brass, offering excellent corrosion resistance and durability. With a commitment to precision and craftsmanship, we ensure that our Press Knocked Inserts meet the highest standards of quality, making them a reliable choice for various industrial applications.

Key Features of Press Knocked Inserts

Manufacturing Process:

Produced by a press-knocking method, these inserts are formed from a solid piece of metal to ensure tight tolerances and robust thread formation without secondary machining.Material:

Typically fabricated in premium brass (with options available in other alloys), which provides superior resistance to corrosion and consistent performance in demanding environments.Thread Integrity:

The press-knocking process creates a clean, well-defined thread that enhances the holding power and minimizes the risk of stripping, even in softer or thin materials.Design Efficiency:

Their compact, low-profile design allows for installation in applications with limited space while still providing a durable, secure threaded connection.

Technical Specifications (Example Values)

| Parameter | Specification (Typical) |

|---|---|

| Material | Brass (e.g., UNS CA‑360) |

| Thread Sizes | Available in a range (e.g., M3 to M12) |

| Insert Length | Typically 1.25 to 1.5× the nominal thread diameter |

| Process | Press-knocked (cold-forged) |

| Finish | Natural polished brass |

Note: Exact dimensions and tolerances can be customized per customer requirements.

Applications of Press Knocked Inserts

Fastening in Soft Materials:

Ideal for repairing or reinforcing threads in plastics, aluminum, or die-cast components without causing additional damage.Assembly & Repair:

Commonly used in industrial, automotive, and consumer applications where durable, long-lasting threads are needed.Cost-Effective Production:

By eliminating secondary machining, the press-knocking process reduces production time and costs while ensuring consistent quality.

Advantages

Enhanced Strength:

The press-knocked design provides a robust, accurately formed thread that significantly improves the load-bearing capacity of the joint.Consistent Quality:

The manufacturing process ensures high repeatability and precise dimensions, which is crucial for high-volume production.Corrosion Resistance:

Brass construction offers excellent protection against corrosion, making these inserts reliable for both indoor and outdoor applications.Versatility:

Available in various sizes and thread specifications, these inserts can be tailored to meet specific design requirements in a wide range of industries.

By selecting Conex Metals’ Press Knocked Inserts, you gain a high-performance, cost-effective solution for creating or repairing threaded connections in challenging materials. Their precise manufacturing and durable construction ensure that your assembly maintains strong, reliable fastening over time.