Stainless Steel pressed parts Stainless Steel pressed components

Stainless Steel pressed parts Stainless Steel pressed components

Conex is one of the leading manufacturers and exporters of Stainless Steel Pressed Parts from Jamnagar, India. We have been supplying Stainless Steel Pressed Parts to the world market for many decades. Our state-of-the-art manufacturing facility, advanced machinery, and rigorous quality controls ensure that every component meets the highest standards of performance and durability.

Conex is one of the leading manufacturers and exporters of Stainless Steel Pressed Parts from Jamnagar, India. We have been supplying Stainless Steel Pressed Parts to the world market for many decades. Our state-of-the-art manufacturing facility, advanced machinery, and rigorous quality controls ensure that every component meets the highest standards of performance and durability.

Price US$ 9.50/kilogram, Click here to order.

Material Grades

We utilize premium grades of Stainless Steel to cater to diverse industrial applications. Our commonly used grades include:

| Grade | Properties | Applications |

|---|---|---|

| Stainless Steel 304 | Excellent corrosion resistance, good formability, high strength | Food processing equipment, architectural panels, enclosures |

| Stainless Steel 316 | Superior corrosion resistance, especially in chloride environments | Marine components, chemical processing, medical devices |

| Stainless Steel 430 | Magnetic, good corrosion resistance, cost-effective | Automotive trim, household appliances, industrial fittings |

Manufacturing Process

Our manufacturing process is designed for precision and repeatability, ensuring high-quality output in every batch. The key stages include:

| Process Stage | Description | Machinery/Tools Used |

|---|---|---|

| Raw Material Inspection | Comprehensive verification of Stainless Steel quality and grade | Automated material testing systems |

| Die & Tooling Design | Custom-designed dies and tooling using advanced CAD/CAM software for optimal part geometry | CAD/CAM systems, simulation software |

| Pressing & Forming | High-pressure forming process that shapes Stainless Steel sheets into complex components | Hydraulic Press Machines, CNC Stamping Equipment |

| Trimming & Finishing | Precision trimming, deburring, and surface treatments (including passivation, polishing, and powder coating) | CNC Trimmers, Deburring Machines, Finishing Equipment |

| Quality Assurance | Rigorous inspection of dimensions and surface finish using cutting-edge metrology tools | Coordinate Measuring Machines (CMM), Optical Scanners |

Machinery Used

Our production facility is equipped with advanced machinery to ensure accuracy and efficiency:

- Hydraulic Press Machines: For high-pressure forming operations.

- CNC Stamping Machines: To achieve consistent and precise geometries.

- Die Cutting Presses: For accurate trimming and clean edges.

- CNC Deburring & Finishing Equipment: To deliver superior surface finishes and tight tolerances.

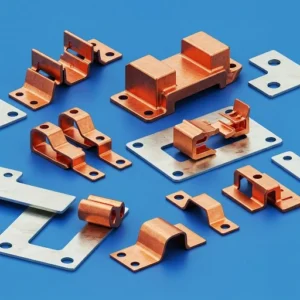

Typical Parts Produced

We manufacture a broad range of Stainless Steel Pressed Components tailored to various industrial needs. Common parts include:

- Structural Brackets and Supports

- Enclosures and Housings

- Panel Assemblies and Decorative Covers

- Industrial Fittings and Connectors

- Components for Food, Medical, and Chemical Industries

Surface Finishes & Coatings

To enhance both functionality and aesthetics, we offer a variety of finishing options:

| Finish Type | Characteristics | Ideal For |

|---|---|---|

| Polishing | Smooth, reflective finish with enhanced aesthetic appeal | Architectural elements, decorative components |

| Passivation | Chemical treatment to enhance corrosion resistance | Medical devices, food processing equipment |

| Powder Coating | Durable, uniform finish that adds extra protection against wear and corrosion | Industrial applications, automotive trim |

Technical Specifications & Tolerances

Our products are manufactured with exacting specifications to meet diverse industrial standards:

| Parameter | Typical Range | Tolerance |

|---|---|---|

| Thickness | 0.5 mm to 12 mm | ±0.1 mm |

| Dimensional Accuracy | Custom design dependent | ±0.05 mm to ±0.2 mm |

| Surface Roughness (Ra) | 0.8 µm – 3.5 µm | As per client specifications |

Turnaround Time

We pride ourselves on efficient production and prompt delivery. Our standard turnaround time is 4-6 weeks from order confirmation to final delivery, ensuring timely execution without compromising quality.

Frequently Asked Questions (Q&A)

Q: What Stainless Steel grades do you use for your pressed parts?

A: We use premium grades such as Stainless Steel 304, Stainless Steel 316, and Stainless Steel 430, each selected based on the required strength, corrosion resistance, and application-specific properties.

Q: What types of components are manufactured from your Stainless Steel pressed parts?

A: Our components range from structural brackets, enclosures, and panel assemblies to industrial fittings, decorative covers, and specialized parts for the food, medical, and chemical industries.

Q: What finishing options are available for your Stainless Steel pressed components?

A: We offer multiple finishing options including polishing for aesthetic appeal, passivation for enhanced corrosion resistance, and powder coating for additional protection and durability.

Q: How do you ensure the quality and precision of your components?

A: Our products undergo stringent quality assurance processes, including detailed inspections using CMM and optical scanners, to ensure that all components meet the specified dimensions and surface finish standards.

Q: What is your typical turnaround time for orders?

A: Our standard turnaround time is 4-6 weeks from order confirmation, although specific timelines may vary depending on order complexity and volume.