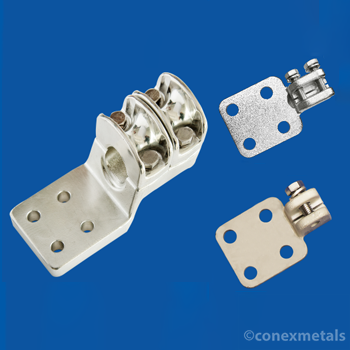

Aerial Cast Lugs Aerial Lugs Aerial Cast Connectors Spade connectors Spade lugs for Transformers: The Power of Bronze and Copper

Bronze Cast Lugs-Bronze Aerial lugs Copper cast lugs Transformer lugs Transformer connectors Bronze Spade Terminals Spade connectors – these Bronze and Copper spades are crucial on the intricate world of power distribution, every component plays a crucial role in ensuring the efficient and safe transfer of electricity. Today, we’re focusing on a critical yet often overlooked component: aerial cast lugs for transformers, specifically those made from bronze and copper. These unassuming pieces of hardware are essential in connecting transformers to overhead power lines, forming a vital link in our electrical infrastructure.

What Are Aerial Cast Lugs Transformer connectors Spade lugs AKA Aerial Lugs Aerial connectors from Bronze and Copper?

Aerial cast lugs are specialized connectors designed to securely attach power lines to transformers in overhead electrical systems. They serve as the bridge between the flexible conductors of power lines and the rigid terminals of transformers. The term “cast” refers to the manufacturing process, where molten metal is poured into molds to create these precisely shaped components.

The Bronze and Copper Advantage

When it comes to aerial cast lugs, bronze and copper stand out as materials of choice. Here’s why:

Bronze Lugs:

- Corrosion Resistance: Bronze, an alloy primarily of copper and tin, offers excellent resistance to corrosion, crucial for components exposed to the elements.

- Strength: Bronze provides the necessary mechanical strength to maintain a secure connection under various stresses.

- Conductivity: While not as conductive as pure copper, bronze still offers good electrical conductivity.

- Cost-Effective: Bronze can be a more economical choice for certain applications, offering a balance of performance and cost.

Copper Lugs:

- Superior Conductivity: Copper is renowned for its excellent electrical conductivity, ensuring minimal power loss.

- Heat Dissipation: Copper’s thermal conductivity helps in dissipating heat, crucial in high-current applications.

- Malleability: The malleability of copper allows for easier installation and maintenance.

- Corrosion Resistance: While not as resistant as bronze, copper still offers good corrosion resistance, especially when treated or alloyed.

Key Features of Quality Aerial Lugs Aerial Cast Lugs

- Precision Casting: High-quality Aerial lugs Bronze Aerial Lugs are cast with precision to ensure a perfect fit and optimal electrical contact.

- Surface Finish: A smooth surface finish reduces electrical resistance and prevents hotspots.

- Compatibility: Designed to be compatible with a range of conductor sizes and types.

- Durability: Built to withstand extreme weather conditions, mechanical stresses, and thermal cycling.

- Easy Installation: Features like guide marks or special designs for easy alignment during installation.

Applications and Importance of Aerial lugs

Aerial cast lugs for transformers are critical in various settings:

- Residential power distribution

- Industrial power systems

- Utility-scale power transmission

- Renewable energy integration (e.g., connecting solar or wind farms to the grid)

Their importance cannot be overstated. A failure in these connectors can lead to:

- Power outages

- Electrical fires

- Increased maintenance costs

- Reduced efficiency in power distribution

Choosing Between Bronze and Copper

The choice between bronze and copper lugs depends on several factors:

- Environmental Conditions: In highly corrosive environments, bronze might be preferred.

- Current Capacity: For very high current applications, copper’s superior conductivity might be necessary.

- Budget Constraints: Bronze can offer a more cost-effective solution in some cases.

- Weight Considerations: Copper is denser than bronze, which might be a factor in some installations.

Installation and Maintenance

Proper installation and regular maintenance of aerial cast lugs are crucial:

- Use of proper torque when tightening connections

- Regular inspections for signs of wear, corrosion, or loosening

- Cleaning of connections to prevent buildup of corrosive materials

- Thermal imaging to detect hotspots indicative of poor connections

The Future of Aerial Cast Lugs

As our power infrastructure evolves, so too do the components that support it. Future developments in aerial cast lugs might include:

- Advanced alloys for even better performance

- Smart lugs with embedded sensors for real-time monitoring

- More environmentally friendly manufacturing processes

- Designs optimized for easier installation and maintenance

Conclusion

Aerial cast lugs for transformers, whether made of bronze or copper, are small but mighty components in our power distribution systems. They exemplify how material science and precision engineering come together to keep our lights on and our world powered. As we continue to rely more heavily on electricity in our daily lives, the role of these unassuming connectors only grows in importance.

The next time you look up at power lines or a transformer on a pole, remember the critical role played by these bronze and copper marvels in bringing electricity safely and efficiently to our homes and businesses.

Related Terms:

Bronze aerial lugs

Overhead line lugs

Electrical aerial connectors

Power line terminal lugs

Transmission line lugs

Distribution line connectors

Material-Specific Terms

Bronze electrical lugs

Copper alloy aerial connectors

Tin-bronze aerial lugs

Leaded bronze lugs

Marine-grade bronze connectors

Corrosion-resistant aerial lugs

Application-Specific Terms

Utility pole lugs

Substation aerial connectors

High-voltage aerial lugs

Medium-voltage line connectors

Overhead conductor lugs

ACSR cable lugs

Technical Specifications

Compression aerial lugs

Bolted aerial connectors

Tubular bronze lugs

Tinned bronze aerial lugs

Dual-rated aerial lugs

UL listed aerial connectors

Size and Compatibility

Large gauge aerial lugs

Multi-conductor aerial connectors

Parallel groove aerial clamps

Tapered pin aerial terminals

Wedge-type aerial connectors

Narrow tongue aerial lugs

Installation and Maintenance

Hot-line aerial lug installation

Aerial lug crimping tools

Overhead line lug replacement

Aerial connector maintenance

Weatherproof aerial lug sealing

Industry-Specific Terms

Utility-grade aerial lugs

Telecom aerial connectors

Railway overhead line lugs

Solar farm aerial terminals

Wind turbine power connectors

Brands and Manufacturers

Burndy aerial lugs

Thomas & Betts overhead connectors

Panduit aerial terminals

Hubbell power connectors

3M electrical lugs

Standards and Certifications

ANSI aerial lug standards

IEEE approved overhead connectors

NEMA rated aerial lugs

RoHS compliant bronze connectors

CSA certified aerial terminals

Performance-Related Terms

High-conductivity aerial lugs

Vibration-resistant line connectors

Heat-cycling resistant aerial terminals

Fatigue-resistant overhead lugs

High-tensile strength aerial connectors

Comparison and Alternatives

Bronze vs aluminum aerial lugs

Mechanical vs compression aerial connectors

Traditional vs innovative aerial lug designs

Cost-effective aerial terminal solutions

Eco-friendly overhead line connectors

Commercial Terms

Wholesale aerial lugs

Bulk buy overhead connectors

Custom bronze aerial terminals

Aerial lug suppliers

Power distribution hardware distributors