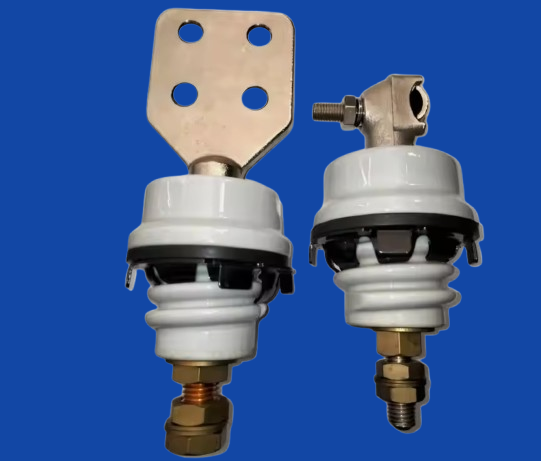

Bronze Transformer Spades Bronze NEMA spaced Transformer spade terminals (9/16″ Bore and 1-3/4″ spacing). Tinned Bronze Transformer Spade Terminals

For stud to single or multiple bus bar vertical takeoff. For use with aluminum or copper compression or bolted type lugs. Manufactured from high Copper content alloy and electro- Tin plated. Comes With Bronze Studs Copper Studs Copper terminal lugs Grounding Lugs and Compression connectors of Bronze, Aluminum, Copper or Aluminum Bronze

Bronze Spades for Transformers: Ensuring Reliable Connections with NEMA Spacing and Tin Plating Options

In the world of electrical power distribution, the seemingly small components often play crucial roles in ensuring system reliability and efficiency. Among these components, bronze spades for transformers stand out as essential elements in creating secure and durable electrical connections. This article delves into the specifics of bronze spades, their application in transformers, the importance of NEMA spacing, and the benefits of tin plating.

Understanding Bronze Spades

Bronze spades, also known as terminal spades or lug terminals, are conductive connectors used to join electrical wires or cables to transformer terminals. Made primarily from bronze, an alloy of copper and tin, these components offer an excellent balance of electrical conductivity, mechanical strength, and corrosion resistance.

Key Features:

- Material Composition: Typically made of 90/10 bronze (90% copper, 10% tin)

- Design: Flat, paddle-shaped end for secure connection to transformer bushings

- Hole Pattern: Accommodates various bolt sizes for different current ratings

- Barrel: Crimped or compression-fit to the conductor

Bronze Spades and Spade Terminal Application in Transformers

Bronze spades play a critical role in transformers by:

- Providing a secure termination point for incoming and outgoing conductors

- Ensuring efficient power transfer with minimal resistance

- Withstanding high temperatures and electrical stresses

- Offering easy installation and maintenance

Size: 4 Hole, 6 hole, 8 hole, 12 hole and 5/8″ , 3/4″ 1″ and 11/4″ Threads

NEMA Spacing: Ensuring Standardization and Safety

The National Electrical Manufacturers Association (NEMA) has established standard spacing requirements for electrical connections, including those in transformers. NEMA spacing for bronze spades refers to the standardized distances between connection points.

Importance of NEMA Spacing:

- Safety: Prevents accidental contact between conductors of different phases or polarities

- Standardization: Ensures compatibility across different manufacturers and equipment

- Performance: Optimizes electrical clearance and creepage distances

- Ease of Installation: Facilitates proper alignment and connection of conductors

Common NEMA spacing for transformer applications includes:

- NEMA 1-hole spacing: 1.75 inches (44.45 mm)

- NEMA 2-hole spacing: 1.75 inches (44.45 mm) between holes

Tin Plating: Enhanced Protection and Performance

While bronze itself offers good corrosion resistance, some applications benefit from additional tin plating on bronze spades.

Advantages of Tin Plating:

- Corrosion Resistance: Provides an extra barrier against environmental factors

- Reduced Contact Resistance: Enhances electrical conductivity at the connection point

- Improved Solderability: Facilitates easier soldering when required

- Visual Inspection: Allows for easy identification of proper connections

Considerations for Tin Plating:

- Cost: Adds to the overall cost of the component

- Thickness: Typically ranges from 3 to 5 microns

- Application Method: Usually electroplated for uniform coverage

Choosing Between Tin-Plated and Non-Plated Bronze Spades

The decision to use tin-plated or non-plated bronze spades depends on various factors:

- Environment: Highly corrosive environments may benefit from tin plating

- Temperature: Very high operating temperatures may affect tin plating

- Cost Considerations: Non-plated spades are generally more economical

- Regulatory Requirements: Some applications may specify plated or non-plated components

Conclusion

Bronze spades for transformers, whether tin-plated or not, are crucial components in ensuring reliable electrical connections. By adhering to NEMA spacing standards and considering the benefits of tin plating, engineers and technicians can optimize transformer performance, safety, and longevity. As with any electrical component, proper selection, installation, and maintenance of bronze spades are essential for the overall efficiency and reliability of power distribution systems. We also offer Aluminium mechanical connectors and mechanical Aluminum lugs for the electrical industry. mainly control panel and transformer manufacturers in the USA. Our range of Hotline clamps is also used widely among overhead transmission line equipment manufacturers and service providers with a great success.