Copper Studs and Threaded Studs: Essential Components for Transformer Bushings

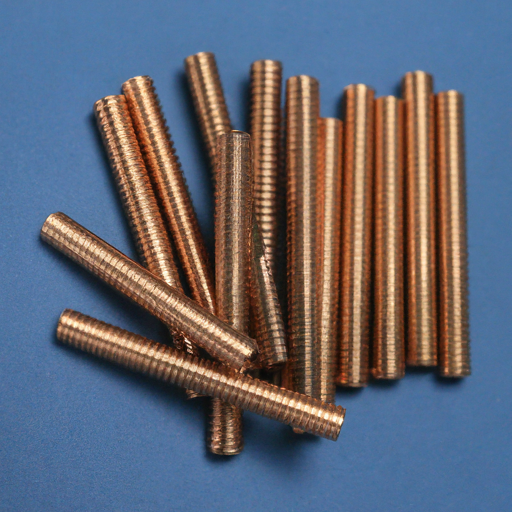

Conex is a leading manufacturer exporter and supplier from India of Copper studs Copper Threaded rods Full Threaded copper studs, Half threaded copper studs, Copper threaded rods and studs for transformer bushings. These are made by roll threading of Copper in 3/8″ , 1/2″, 5/8″ and 1″ UNC or UNF UNEF threads. In the world of electrical power distribution and transformer technology, the smallest components can play crucial roles in ensuring efficiency, safety, and longevity. Copper studs and threaded studs used in transformer bushings are perfect examples of such critical elements. This comprehensive guide will explore these components, their importance, types, and applications in transformer bushings.

Understanding Transformer Bushings

Before delving into studs, let’s briefly review transformer bushings:

- Transformer bushings are insulating devices that allow an electrical conductor to pass safely through a grounded conducting barrier, such as a transformer tank.

- They provide electrical insulation and mechanical support for the conductors.

The Role of Copper Studs and Threaded Studs

Copper studs and threaded studs serve several essential functions in transformer bushings:

- Electrical Conductivity: Copper’s excellent conductivity ensures efficient power transmission.

- Mechanical Support: They provide a secure connection point for conductors and other components.

- Heat Dissipation: Copper’s thermal properties help in managing heat generated during operation.

- Corrosion Resistance: Copper naturally resists corrosion, enhancing longevity.

Types of Studs Used in Transformer Bushings

1. Solid Copper Studs

- Made from high-purity copper

- Excellent conductivity and strength

- Used in high-current applications

2. Threaded Copper Studs Copper Threaded Rods (full threaded and half Threaded studs of Copper)

- Feature precision threading for secure connections

- Allow for easy assembly and disassembly

- Available in various thread sizes and pitches

3. Copper-Clad Steel Studs

- Steel core for strength, copper exterior for conductivity

- Combine the benefits of both materials

- Ideal for applications requiring high mechanical strength

4. Tinned Copper Studs

- Copper studs with a tin coating

- Enhanced corrosion resistance

- Improved solderability

Key Considerations in Stud Selection

When choosing studs for transformer bushings, consider:

- Current Rating: Ensure the stud can handle the maximum current flow.

- Voltage Rating: Select studs appropriate for the system voltage.

- Environmental Factors: Consider exposure to moisture, chemicals, or extreme temperatures.

- Mechanical Strength: Choose studs that can withstand the mechanical stresses involved.

- Compatibility: Ensure compatibility with other bushing components and conductors.

- Standards Compliance: Verify compliance with relevant industry standards (e.g., IEEE, IEC).

Installation of Copper full threaded and Copper half Threaded studs

Proper installation is crucial for optimal performance:

- Clean Contact Surfaces: Ensure all contact surfaces are clean and free from oxidation.

- Proper Torque: Apply the correct torque when tightening threaded studs.

- Use of Lubricants: Apply appropriate conductive lubricants to enhance electrical contact.

- Alignment: Ensure proper alignment to prevent mechanical stress.

- Insulation: Properly insulate exposed conductive parts.

Maintenance and Inspection

Regular maintenance ensures longevity and safety:

- Periodically inspect for signs of corrosion, overheating, or loosening.

- Check for proper torque on threaded connections.

- Clean connections and reapply anti-oxidation compound if necessary.

- Replace studs showing significant wear or damage.

Innovations in Stud Technology

The field of transformer bushings and associated components continues to evolve:

- Advanced Alloys: Development of copper alloys with enhanced properties.

- Nanocoatings: Application of nanocoatings for improved conductivity and corrosion resistance.

- Smart Sensors: Integration of sensors for real-time monitoring of connection integrity.

- Eco-Friendly Options: Development of more sustainable and recyclable materials.

Conclusion

Copper studs, Copper threaded studs, Copper half threaded studs, Copper threaded rods are integral components in transformer bushings, playing a vital role in ensuring the efficient and safe operation of power transformers. By understanding their types, selection criteria, and proper installation techniques, engineers and technicians can ensure optimal performance and longevity of transformer systems.

As the energy sector continues to evolve, with increasing demands for efficiency and reliability, the importance of these small yet critical components cannot be overstated. Staying informed about the latest developments in stud technology and best practices in their application will be crucial for professionals in the electrical power industry.

Remember, while this guide provides general information, always consult manufacturer specifications and industry standards for your specific application. When in doubt, seek the advice of a qualified electrical engineer to ensure safe and compliant installations.

TERMS Related to ‘Copper Studs’

General Terms

- Copper studs USA

- American-made copper studs

- Copper electrical studs

- Copper threaded studs

- Copper fasteners US

- Industrial copper studs

- Transformer bushing copper studs

- Electrical panel copper studs

- Switchgear copper studs

- Circuit breaker copper studs

- Substation copper studs

- Solar panel copper studs

- ASTM B187 copper studs

- UL listed copper studs

- ANSI certified copper studs

- NEMA standard copper studs

- High conductivity copper studs

- Oxygen-free copper studs

- 1/4-20 copper studs

- 3/8-16 copper studs

- Metric copper studs USA

- Custom size copper studs

- Fine thread copper studs

- Coarse thread copper studs

- C110 copper studs

- ETP copper studs

- Beryllium copper studs USA

- Tinned copper studs American

- Silver-plated copper studs

- Nickel-plated copper studs US

- Utility grade copper studs

- Commercial copper studs

- Residential copper studs

- Marine grade copper studs USA

- Aerospace copper studs American

- Telecom copper studs US

- US copper stud manufacturers

- Domestic copper stud suppliers

- Custom copper stud fabrication USA

- Wholesale copper studs America

- Bulk copper studs US

- Made in USA copper studs

- Copper stud installation tools

- Copper stud torque specifications

- Copper stud crimping tools US

- Copper stud welding equipment

- Copper stud removal techniques

- Copper stud maintenance USA

- NEC compliant copper studs

- RoHS copper studs USA

- OSHA approved copper studs

- IEEE standard copper studs

- DOE certified copper studs

- NFPA compliant copper studs

- High-performance copper studs

- Corrosion-resistant copper studs US

- Heavy-duty copper studs American

- Precision copper studs USA

- Long-life copper studs

- Temperature-resistant copper studs

- Copper vs brass studs USA

- Aluminum vs copper studs American

- Stainless steel vs copper studs

- Copper stud alternatives US

- Cost-effective copper stud options

- Eco-friendly copper studs USA

- Recycled copper studs American

- Lead-free copper studs US

- Non-toxic copper fasteners

- Sustainable copper studs USA